The angle grinder is a powerful instrument that grinds and cuts metal using a revolving disc whirling at an astonishing speed. Did you realize that the angle grinder can do a lot more?

It is a heavy-duty power tool that can cut, grind, polish, smooth, and sharpen a broad range of materials, including iron, steel, brass, marble, wood, and stone. It is available in battery-powered (cordless) and electricity-powered (corded) variants.

Aside from its most typical application as a grinder, this power tool comes with several abrasive attachments that may be used for a range of chores and activities. Depending on the material you’re working with and the job you need to accomplish, you can select an attachment.

Different Types of Angle Grinder Discs

Angle grinder discs are not all created equal, and each one serves a distinct function. If you’ve recently purchased a high-quality angle grinder and want to improve its efficiency and productivity, read our article below about the ten distinct types of angle grinder discs and their applications.

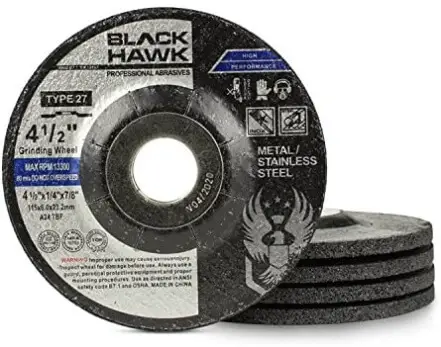

1. Grinding Discs

The primary function of an angle grinder is to grind metal. And it can only be done using grinding discs. With little effort, these discs can effortlessly scratch the metal. These come in a variety of grits. The lower the grit number, the faster the grinder can grind, but at the expense of surface quality. The greater the grit, the slower the cutting will be, and the better the surface polish will be.

Grit counts typically range from 24 to 80. Industrial discs with a higher grit are also available. Grinding discs come in diameters of 4, 4.5, 5, 7, and 9 inches. Flexible Grinding Discs have recently been produced. Some people enjoy them, while others do not. You’ve had your chance.

2. Cutting/ Cutoff Discs

This type of disc is commonly used to cut metal things. Available for most four-inch, five-inch, seven-inch, nine-inch, and even fourteen-inch cutoff saws. As the size grows larger, so does the thickness. Remember to factor in the thickness of the disc when making marks on the things to be cut.

Because it is fragile, this disc is an abrasive disc with reinforcement. Metal Cutting Diamond Discs are also accessible nowadays. They take a long time to cut, but they are quite clean since they don’t leak aluminum oxide powder everywhere.

INOX Cutting Discs are used to cut stainless steel. Both INOX and non-INOX can be used on mild steel. INOX generally signifies that the disc is devoid of Sulphur and Chlorine, which react with Stainless Steel’s Chromium concentration.

Cutting discs are only used for straight cuts, not curved ones. Non-straight cuts cause the disc to lock up, resulting in kickbacks or disc shattering. Also, for deburring, this disc should not be used sideways.

The GRAFF Black metal cutting disc is the only disc that may be used sideways.

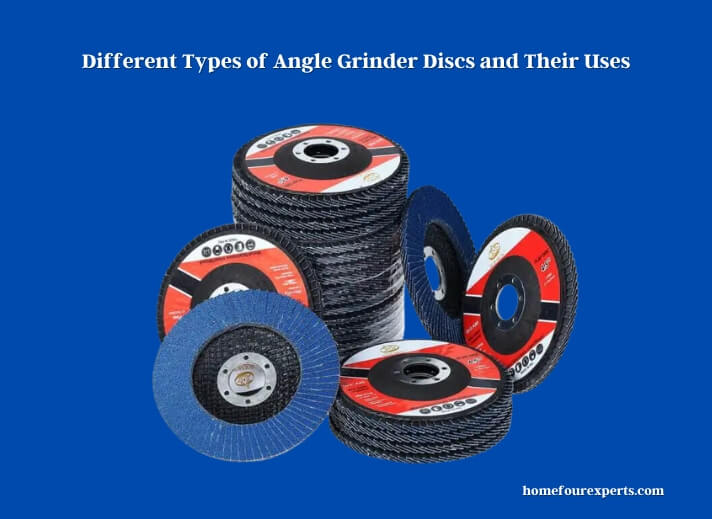

3. Flap Discs

The high-grit grinding discs do a superb job of finishing the surface. However, this is not an improvement. Flap discs are employed to make them more attractive. Sandpaper layered together is used to create these discs. Because they come in various grits, choosing and purchasing the correct disc for the job is simple.

The sole disadvantage of these discs is that they have high production costs, which leads to higher pricing. Grits range in size from 60 to 240 or higher. These discs may be used to carve wood as well, and their applications are not limited. Sizes 4 and 5 inches are available. 4-inch discs are substantially less expensive than 5-inch discs; thus, I usually recommend them.

Both the grinding and flap discs can do the same function in the end. One grinding disc equals five or more flap discs for the same amount of metal removal. This isn’t to say that grinding discs are constantly superior. Flap discs are more commonly used in my manufacturing than grinding discs.

The primary benefit is that they will continue to grind even if they become old. None of my flap discs are ever thrown away. I use them for chamfering on wood, where I can obtain an excellent finish. They scrape less material since they are older. During fillet/chamfer/edging precision processes, this becomes a benefit for woodworkers. Read more: Can You Use an Angle Grinder on Wood

I use the grinding wheel to grind a weld bead. I use a flap disc to complete it without damaging the surface.

4. Buffing Disc

Angle grinder buffing discs come in a variety of shapes and sizes. Non-woven buffing discs are offered for stainless steel polishing. They do include minute abrasive particles that aid in preserving the typical Chrome hue of stainless steel. They are used without any buffing chemicals and are operated dry.

They resemble Scotch-Brite substance in appearance. The most common material utilized in this disc is fiber. This disc may also be used to remove rust from metal items while preserving the metal. Before being used on Angle Grinders, this disc was developed for Bench Grinders. The brown disc on the left in the image above is an 8-inch Bench Grinder Buffing Wheel.

5. Polishing Disc

This is a cotton disc that has been compressed. Metal polishing is the most common use. There are two sizes available: 4 inches and 5 inches. Velcro-type polishing pads are used for automotive polishing. The metal is first polished using a polishing compound before being polished with this disc.

This gives the surface a mirror sheen, and the polishing liquid coats the workpiece in a protective layer. Polishing Compounds and Polishing Liquids/ Gels are two different products. The majority of them contain a fine abrasive powder. Remember! Other polishing substances are not the same as automotive polishing wax.

Angle grinders are not suitable for automotive polishing. The paint gets ripped off by using incorrect polishing chemicals and high RPMs. Woolen Polish discs are available for use with automotive polishers. It is highly suggested that you get expert help.

Buffing/polishing discs, on the other hand, buffing/polishing discs may be used with ease on non-painted engine components. Polishing Royal Enfield UCE engines is an example. Read more: Differences Between Die and Angle Grinder

6. PVA Abrasive Disc

These are finer grit abrasive discs for general use, with grits ranging from 400 to 3000. With these discs, steel may be polished to a chrome sheen. Marble, glass, stone, ceramic, wood, and all forms of ferrous and non-ferrous metals are all polished using PVA Abrasive discs.

People have the option of using Sand Papers or PVAs. Because they both have a similar finish. Fine Grit Sandpaper is challenging to come by in some places.

PVA Discs are also tough to come by in some areas. Some people may learn about PVAs for the first time due to reading this article. This PVA Disc should always be used dry. It should never be used with a polishing product. Silicon carbide powder is fused with Poly Vinyl Alcohol to create PVA Disc. It is also possible to remove paint and corrosion.

Because the disc is made of compressed silicon carbide powder coupled with PVA, it will not clog (Poly Vinyl Alcohol). In some regions, this disc is also known as a Felt-DC Wheel.

7. Wire Cup Brush Wheel

This wheel is commonly used to remove rust from materials, clean surfaces before welding, and clear spatter after stick welding. Wire wheels come in two varieties, one made of steel and the other of brass (Technically, it is Steel Wire itself coated with Brass Color). Steel wheels are used on ferrous materials such as mild steel, stainless steel, and similar metals.

Brass wheels are used on non-ferrous metals such as brass, aluminum, and copper. Steel wheels should not be used on non-ferrous materials since the steel wires will scrape the natural substance rather than remove rusted material or coatings. Instead of Cup type wire wheels, you may choose Flat type wire wheels. Cup wheels that are twisted and non-twisted are also available.

8. Velcro Sanding Pads

This is an Angle grinder sanding attachment. Velcro Pads are offered in two different varieties. One is for a 4-inch Angle Grinder, and the other is for a 5-inch Angle Grinder. Both support the same 125mm (5′′) Sanding Paper. The difference is due to the size of their nuts. M10 Nut is found on 4-inch grinders, and the same type of Velcro Pad should be ordered. M14 Nut is used in the 5-inch grinder.

Depending on the size of the Velcro Pad, I recommend purchasing the Angle Grinder Spindle if you’re using this accessory with a drilling machine. By utilizing this spindle, the Velcro Pad may be readily affixed to any drilling machine.

The sole disadvantage of this arrangement is that just one side of the sanding paper wears down during use, leaving the central portion of the paper untouched. If you’re looking to buy a Drum Sander, this is the most affordable alternative. The Velcro Pad is really an accessory for an Orbital Sander. As a result, Orbital Sander discs can be used.

9. Backing Pad

This Backing Pad attachment is similar to the Velcro attachment in that it attaches to the middle nut directly. In this instance, too, the user must purchase the nut-based on the size of his Angle Grinder. M10 or M14 are the two options. Compared to the Velcro Pad, the Backing Pad attachment is far more adaptable. Because the sanding disc may be utilized 70% of the time. Backing Pads are adaptable.

Plastic/ Fiber or Rubber Backing Pads are available on the market. Rubber pads are easy to use and perform without a hitch. When it comes to flexibility, plastic pads aren’t perfect. There are a variety of grit levels available for both Velcro and Backing pads, ranging from 60 grit to 220 grit and beyond. In India, finding a 2000 grit sandpaper is difficult.

These sand discs are more costly than standard Backing pad discs because of the Velcro strip. Both have advantages and downsides in general. But, in any case, both are relatively inexpensive to purchase. The user can try out each one before settling on his favorite one.

10. Ceramic Sanding Discs

These discs offer the best value for money; while they are initially more expensive than zirconia and aluminum oxide, they last significantly longer and deliver consistent results.

Because ceramic is a more demanding abrasive, it is appropriate for heat-sensitive materials like stainless steel, nickel alloy, and titanium because it has less ceramic friction and operates cooler than aluminum oxide and zirconium.

Conclusion

The angle grinder is the right tool for the job, whether you’re completing metal projects or cutting tile. Thanks to its strong motor and high RPM, it’s the go-to tool for taking on several chores with the correct attachments and ultimate adaptability, thanks to its strong motor and high RPM.

Select the appropriate accessories and discs to convert your angle grinder into a sander, polisher, buffer, grinder, or multi-material cutter, select the appropriate accessories and discs.

Relevant Resources:

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.