In this era of modern engineering, many sophisticated tools are used for many purposes. Engineers can take full advantage of any tool when provided with accurate instruction and information about the tool.

Tools such as centering Gauge, surface gauge, gauge block, etc, are immensely used in manufacturing, and information about these is necessary. Keep with us to get the clear concept about a centre gauge.

What Is the Meaning of Centering Gauge?

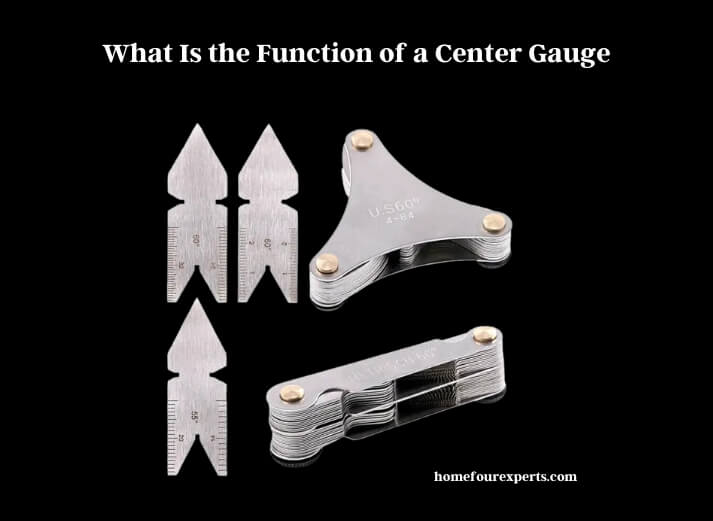

A centering gauge has another name: a fishtail gauge. This tool is small in dimension and is handheld while in use.The size of the tool is approximately 1/4 inches by 3/4 inches.

This is a flat-looking tool used to check the measurement of the angle of tool bits and cut screw threads. This is the most straightforward centering gauge definition you’ll find on the internet.

Home machinists usually use this tool for grinding tool bits by the handheld process. This device is usually available in hand machining tool shops and can come in various gradations for multiple tread measurements.

Function of a Center Gauge

This Sophisticated tool is used for many purposes. We have cited a few workabilities below:

● Grinding and setting thread: a centering gauge is a beautiful piece of tool that mechanics generally uses for grinding, and it is further used when setting thread for cutting tools.

● Lathe works: this tool is utilized most when it’s in the lathe workshops. It can check the angles while the grinding takes place, and it can measure the angles of single-point screw-cutting tool bits.

● Hand grinding: it is commonly seen that workers are utilizing This tool in hand grinding.

A centering gauge and other valuable tools such as feeler gauges, fishtail gauges, screw gauge pitch are used every day in the engineering workshops. They are also seen in household mechanical activities.

What Will Be Get From This Centering Gauge

This tool is commonly made of stainless steel and pure iron. High-quality metals are used to manufacture this tool to withstand high-performance load and provide its user more longevity.

A satin chrome finish is also seen in the structure of this tool. This gives an attractive dimension to its appearance.

Deeply etched graduations are permanently put on the tool for better usage efficiency. The edge profile of the tool is also grounded with the utmost care.

The graduations on this tour are so precise that you can even measure small distances such as 1/14, 1/24,1/32 of an inch. These precise graduations made this tool exclusively worthwhile.

What Is a Gauge Block?

A gauge block is a helpful tool commonly used in metal construction workshops and civil engineering sites. It is a block construction made of metal or ceramic with two opposite faces that are precisely ground flat and parallel to each other.

The primary usage of these tools is a reference for the calibration process of measurement of equipment used in machine shops. Gauge blocks can be utilized for creating a correct length in a wide range. They are seen as the primary source of standardization of length measurement in the industries.

The gauge blocks can be taken from their sets and be formed into a stack that makes up the dimensions required by the workshop men or engineers.

An approximate temperature of 20°c is recommended while using the blocks to calibrate and measure. This optimum temperature is recommended so that the user’s measurements don’t get affected by thermal expansion.

To protect the blocks from wear damage, blocks made of more rigid materials such as tungsten carbide are added at each end of the measurement stacks.

The experts use the fewest blocks so size errors can be avoided. Achieving the ultimate precision in the craft is taken as the most priority by the engineers, and so they utilize these blocks.

How Do You Use a Center Gauge Tool?

Center gauges are used side by side with other tools and cutter grinders. When the threading tool bits are hand-grinded, center gauges are utilized the most.

If you reach the point when the tool bits are grounded to the precise required angle, the center gauges can be utilized for setting the tool perpendicular to the workpiece.

A center gauge is put to use when you need to set thread cutting tools. Four scales are available on the Gauge that is used in the process of determining the Total number of threads per inch.

FAQs

What Is a Feeler Gauge Used for?

Engineers in the workshops use the feeler gauge most often. A feeler gauge is used for measuring the gap widths and quantity of clearance between two machine parts.

What Is a Surface Gauge?

The primary purpose of using a surface gauge is to mark off castings and verify the accuracy of plain surfaces.

What Is the Use of a Gauge?

The word Gauge is also used with another spelling, ‘gage.’ These devices are used in manufacturing and engineering to determine and measure the size of any dimension and compare if the given dimension is larger or smaller with the required dimension.

Gauges can also be seen to be used as a reference standard for any measurement.

This tool is used to ensure the accuracy of dimensional quantity and mechanical preciseness. They are commonly used to measure the height, width, depth, diameter, volume, etc., of any apparatus.

What Is the Use of a Screw Pitch Gauge?

Screw pitch gauges are also known as thread gauges. These are primarily used for determining the measurement of pitch and lead of other apparatuses such as screw threads.

This convenient tool saves time of use by eliminating any need to measure and calculate any threaded tool’s pitch.

Conclusion

Centering Gauge and other tools alike are immensely useful in engineering, so they are used every day by many workshop men around the globe. So, this tool is mostly used.

Detailed information on these tools is mandatory for taking advantage of these beautiful devices.

Featured image credit: Amazon.com

Read more:

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.