If you are a craft enthusiast, you must be familiar with wet saws and table saws. A table saw is mostly used to cut wooden materials and wood. On the other hand, you generally use a wet tile saw to cut through tiles.

But, can a wet so be used as a table saw? Our answer would be, “Yes, it’s a bit complicated. Let’s discuss it”. We cannot just tell you the exact answer to that question right away.

That’s why we brought a detailed discussion and analysis on this topic in this very article. For your convenience, we have laid down the answers to a few other related questions as well. So, bear with us for a few minutes and get your needed info.

What Is a Wet Tile Saw? [ and How Does It Work?]

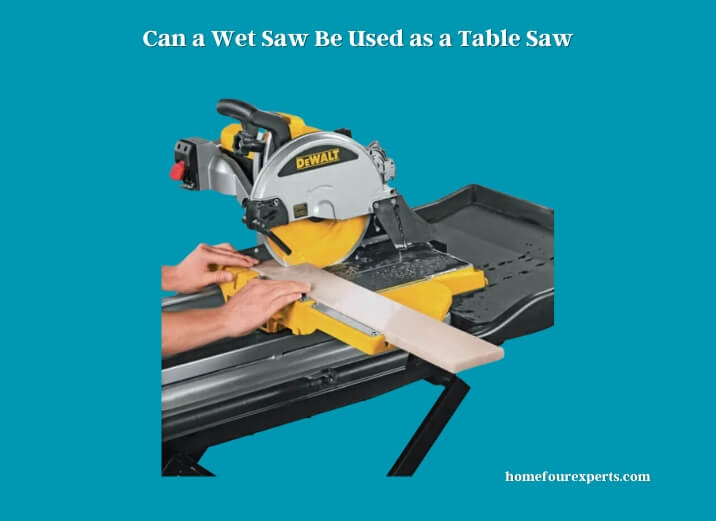

A wet saw is a cutting tool that uses circular blades and water to cut through tiles and other hardened flat objects. It uses a dedicated pump to pump water into the blade area where cutting action occurs. As the water keeps the heat at bay, the circular blade can easily pierce through even the toughest types of tiles.

Furthermore, the blade of a wet saw cutter does not have large teeth. As a result, you can cut through delicate objects without any difficulties.

What Is a Table Saw? [and How Does It Work?]

A table saw is a dedicated machine for cutting wooden materials. It has an electrically powered motor that rotates a circular blade. Also, the edge is equipped with large teeth that can cut deep into the wooden structures. Furthermore, a table saw is mounted on an arbor, giving the user an advantage to carve a wooden object.

A table saw’s cutting efficiency and fineness are mediocre to low grade. As it is not designed to make fine cuts, it cannot miss intricate precision. But, thanks to its large-toothed blade, it can robustly cut through hard and broad wooden structures very easily.

Wet Tile Saw vs. Table Saw

Although wet tile saws and table saws are cutting tools, they have a few robust differences. The difference between them makes them suitable for two distinct categories of jobs. Let’s see how they differ from each other in the below discussion:

Blade Structure:

- For a tile saw, the blade doesn’t have very large teeth. Since tiles are flat and sheetlike sheet-like structures, a wet tile saw blade does not need large teeth to cut through them. On the other hand, it uses grinding force to make fine cuts through the tiles.

- On the flip side, for a table saw, the blade will have large size teeth. Since wood comes in various types and sizes, a large toothed blade is needed to cut them into small pieces. Furthermore, in the case of cutting wood, cutting accuracy is not a big matter of concern. Rather, the sheer force quantity is the key factor for cutting large loads of wood.

The Nature Of Motor:

- In the case of a [amazon link=”B000J0BG7W” title=”wet tile saw” /], the motor RPM is much higher relative to table saws. Because tile cutting is heavier than woodcutting, the motor needs to run very fast to drive the blade. Since tiles are enormously hardened objects, they require high-speed friction from the blade to be cut very finely. As a result, almost all types of tile saws in the market are seen to be equipped with very high RPM motors.

- On the other hand, in the case of a table saw, the motor does not need to have high speed to cut through a wooden structure (because wood is much softer than tiles). Furthermore, rather than having a high RPM feature in the motor, high torque is needed to drive the blades through robust wood structures. That is why you’ll see that all types of table saws will have a high torque but low RPM motor.

Heat Dissipation

- A signature feature of wet tile saws is its water pumping mechanism that cools down the blade in real-time as it cuts through. Also, the whole time it conducts cutting action, a dedicated water pump sprays water to the blade. As a result, that dust generation from cutting the tiles is reduced.

Moreover, thanks to the watering mechanism, the blade doesn’t create sparks when grinding its teeth into the tile’s body.

- But, for table saws, there is very little chance of spark generation in the time of cutting action. Furthermore, since the motor RPM of a table saw is not that high, it doesn’t create excessive heat. Because of all these reasons, there is no water cooling mechanism in table saws (as it’s not needed).

Freedom of Blade-adjustment:

- As wet tile saws have a blade situated on the arbor’s surface, you will have higher freedom for adjusting the blade’s position and angle. Furthermore, you wouldn’t need to impart too much effort to raise the blade or bring it down.

- On the contrary, for table saws, you’ll see that the blade is poking its head from underneath the table ( through a dedicated window carved in the middle of the dip). This means that you will have no option to adjust the blade’s position in a table saw. This is why, compared to wet tile saws, table saws are less convenient to work with (for cutting concrete structures like tiles, etc.).

Can a Wet Saw Be Used as a Table Saw?

In simple terms, Yes. But it is not ideal. If you want to use a wet tile saw as a replacement for a table saw, you must know the aspects we have cited below.

To state in short, using a wet tile saw as a table saw is a bad idea. It’s because wet saws are not meant for cutting through robust objects like wood. But, technically speaking, you can still cut wood with a wet saw. Although it wouldn’t be a very efficient cutting action, you can cut through the wood with a wet saw.

But, we must tell you that the blade of a wet saw is not equipped to perform deep cuts. Rather, this type of blade is suitable for cutting sheetlike sheet-like objects. This is why we don’t recommend using a wet tile as a table saw.

Can a Wet Tile Saw Cut Wood?

As mentioned in the above discussion, a wet tile saw can cut through wood. But, it will not be recommendable to do so. It’s because a damp saw won’t be as efficient as a table saw in cutting a wooden object. If you need to cut through flat and sheetlikesheet-like wooden structures, you can use a wet tile for the timing being. But it should never be a permanent tool for cutting woods.

Can a Wet Saw Also be Used to Cut Plexiglass Like a Table Saw?

Yes, table saw tips for plexiglass can also be applied to a wet saw. When cutting plexiglass with a wet saw, use a fine-toothed blade to minimize chipping and cracking. Ensure that the plexiglass is properly supported and use a slow, steady feed rate to achieve clean, smooth cuts.

Conclusion

There you go, congrats! You just completed reading all the unnecessary info regarding wet tiles and table saws. Now you know all there is to know regarding the query “can a wet saw be used as a table saw?”.

The bottom line is that you can use a wet tile as a table saw. But, it’s not recommended. However, if you ever dare to try doing it yourself, we implore you to use proper safety precautions. Best of luck!

Relevant Resources:

- Wet Saw VS Tile Cutter: Which is Best for Your Project

- Can You Use a Wet Saw Without Water?

- Difference Between Marble Cutter and Circular Saw

- Can You Cut Plexiglass With a Table Saw

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.