An angle grinder is a powerful instrument that may be used to cut metal and other solid materials including bricks, aluminum, stone, and concrete. This sort of hand-held power tool has a grinding wheel rather than a cutting blade.

Metal, masonry, and even concrete may be easily cut with a decent angle grinder. Is it, however, a smart idea to cut wood with an Angle Grinder? Consider the following variables before bringing out your favorite angle grinder to maul that would-be piece of lumber.

Angle Grinder for Wood Cutting, Yay or Nay?

Yes, is a hasty and blundering response. However, cutting wood with a metal cutting disc isn’t optimal, and most specialists advise against it. You must know how to use an Angle Grinder for Wood Cutting and which blades to use.

There are, however, substantial risks connected with using an angle grinder for woodcutting, so knowing what to expect will help you remain safe. What exactly is the rationale behind this? Because using an abrasive blade on a grinder to cut a combustible material like wood may be disastrous.

Aside from the apparent danger, there is additional risk involved with utilizing an Angle Grinder for wood cutting.

When utilizing a high-speed power instrument like a grinder to generate a cut on a piece of metal, or even when attempting to cut concrete with a diamond saw blade, there is increased resistance due to the density of the material.

This is not the case with wood, though. When using an Angle Grinder to cut wood, a lightweight material, a small change in posture, such as bending your wrist, might cause the grinder to abruptly reverse direction.

When this happens, your reaction time may be insufficient to reverse the almost instantaneous change, leaving you with an out-of-control grinder spinning at 15,000 RPM. Furthermore, most grinders lack an electrical brake and are slow to stop spinning, and I’m sure you don’t want to stand in the way of a furious grinder traveling through space and time.

Is It Safe to Use an Angle Grinder on Wood?

Yes, of course. An angle grinder can cut wood because it has the strength and capability to do so. That does not mean, however, that an angle grinder is an optimum tool for the job. Although an angle grinder is useful for modest chores, you should think hard before using it on a major project.

Is There a Wood Blade for an Angle Grinder?

When using an angle grinder to cut wood, you’ll need the correct blade. So, let’s have a look at some of the greatest wood-cutting blades on the market.

Let’s start with the question of whether a regular blade can cut wood. This is a common blunder made by novice users, and you should avoid it. Cutting with a standard blade is possible, however, the safety is lacking. The grinder may rise and fly off the table you’re working on if something goes wrong.

You might be gravely injured if you rotate at high speeds. Instead of attempting to use a conventional blade, you should opt for one of the woodcutting blades listed below to assist reduce the danger of an accident while maintaining the smooth and exact appearance of your project.

Angle grinder wood carving disc is a great choice for soft and hardwood carving. It has the necessary strength for wood, but it also has the proper form and design to undertake woodcutting operations with ease. This is one of the alternatives, and others like it, that you should seek if you want to complete the job right.

This option is a wonderful choice because it can cut hardwood, plywood, MDF, and other materials.

What Types of Wood Can I Use an Angle Grinder on

Angle grinders can be used to cut, sand, polish, and sharpen a variety of woods, including hardwoods like oak, maple, cherry, ash, and walnut, as well as softwoods like pine and cedar. Some woods, such as balsa, are too soft for an angle grinder and may be damaged by its powerful cutting action.

Is a Grinder Good for Cutting Wood?

Yes, of course, is the ideal response. Because of its strength and capability, an angle grinder can cut wood. However, this does not rule out the possibility of using an angle grinder to cut wood.

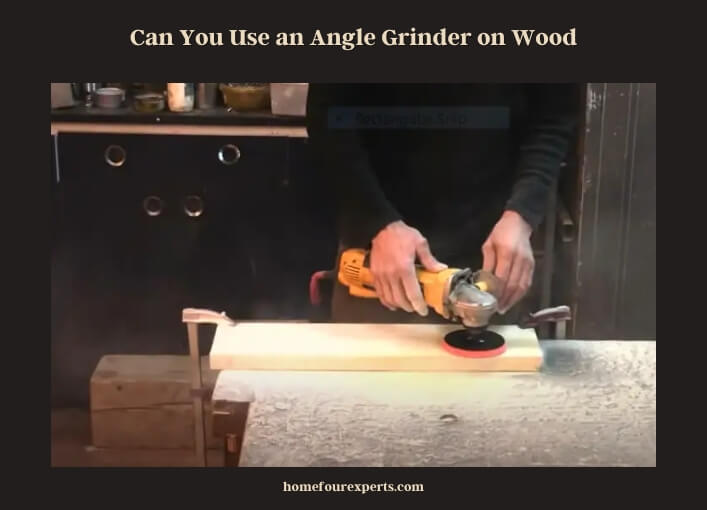

How Do You Use an Angle Grinder to Smooth Wood?

Sanding is the process of abrading the fibers to make the surface feel more homogeneous. This can be done before joining parts or staining the wood.

Wood may be sanded quickly and precisely using an angle grinder. To sand wood with a grinder, follow these steps:

1. Attach the Flap Disc to the Grinder

You’ll need the correct attachment to transform your angle grinder into a sanding tool. Angle grinders may be used with a variety of attachments, but for sanding wood, you’ll need a flap disc.

- This disc is formed from overlapping sandpaper sheets. These sheets are positioned around the disc’s core and will remove a huge amount of wood in a single motion.

- To remove dents and defects from the wood’s surface, an abrasive flap disc is connected at an angle.

- This attachment is inexpensive and will save you a significant amount of time. It can sand wood faster than other equipment, such as a standard sanding block, and it can also perform a better job. It’s also relatively safe, making it a fantastic alternative for DIY enthusiasts and novices.

- Before mounting the flap disc, ensure the power switch is off and your angle grinder isn’t connected to a power source.

- You may pick your flap disc based on the sort of wood you have. The sanding paper comes in grits of 40, 60, 80, 100, and 120, so you may choose the correct one for the wood you’re working with and the desired result.

2. Use Your Angle Grinder

It’s time to switch on your computer now that you’ve fastened the flap disc.

- Using many clamps, secure your wood to a table or stable surface. Because the grinder takes two hands to operate, you must first secure your wood.

- With both hands, hold your angle grinder. To avoid damage, keep your hands away from the flap disc.

- Always start with a heavy-grit flap disc when using an angle grinder. Smooth up the surface with the angle grinder, then use a light-grit flap disc of 100 or 120 for the final touch and to remove the deepest scratches.

- Keep your hands away from the machine and use safety goggles to keep the debris out of your eyes. For further protection, some people prefer to wear a faceguard. Wearing your work gloves is a great way to keep your hands safe.

3. Remove the Saw Dust

- Before going on to the next stage, always remove the sawdust from your angle grinder after sanding the wood.

- If you use a brush or broom, the dust will be dispersed all over the place, and you may inhale it accidentally. Inhaling sanding dust can cause a variety of health problems.

- A vacuum cleaner is a great item to have since it will eliminate all of the dust and keep your workspace clean. Before applying layers of finish or stain, use sticky cloths to remove any remaining dust.

- You may also blow the dust away using compressed air and a robust exhaust system.

- You may also utilize this if your store has a dust collecting system. You may also make your own dust collector at home.

Summary

To get rid of the dust, you can utilize compressed air and a proper exhaust system.

This can be used if your store has a dust collecting system. You may also make your own dust collector using common household items.

To get rid of the dust, you may also utilize compressed air and a proper exhaust system.

You may also utilize this if you have a dust collecting system in your store. You may also make your own dust collector from scratch.

Relevant Resources:

- Bench Grinder VS Angle Grinder: Which One Should You Choose

- Difference Between Angle Grinder and Circular Saw

About This Writer

Hi, I am Eric Devin and I am a professional interior architect. Since childhood, I've always enjoyed DIY projects! And, I have loved to solve simple household problems using essential tools and equipment. I have also acquired a lot of information about basic household tools settings by working with contractors.