Got a new coordinate measuring machine but confused about how to use it? No worries as you have chosen the right platform to seek a solution.

With the advancement of technology, these machines have replaced the age-old hand tools to measure something.

If you need to measure and replace a physical object, this tool is the best one to do so. Both contact and non-contact versions of it are available. The first one works through touch probes and a round object while the second one has lasers and cameras.

However, without further ado, let’s analyze the usages and measuring methods below.

What is a Coordinate Measuring Machine?

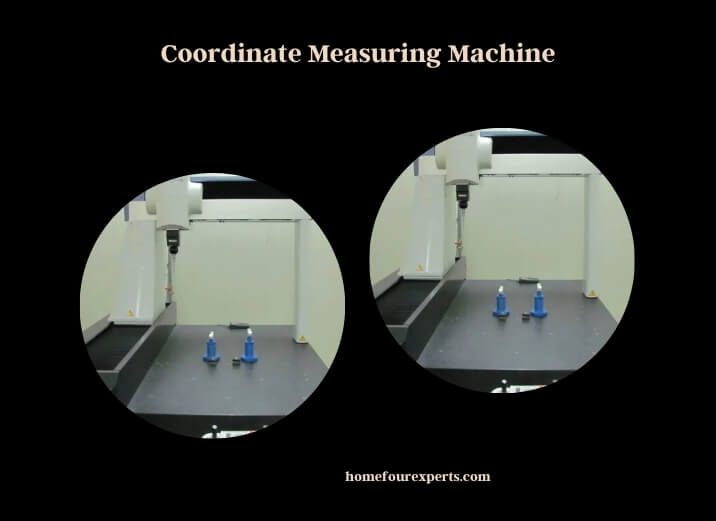

To measure any solid object’s conformity and specifications, a device is used which works with an electronic probe. It senses the discrete points of the object when it is placed on the surface. This device is known as a coordinate measuring machine.

According to Wikipedia, a coordinate measuring machine moves its probes along X, Y, and Z axes. Thus it is engineered for providing three-dimensional vectors.

Main Components of CMM

The device consists of three major components- the machine itself, the probing system, and the controlling system.

The Machine

This indicates the structure of the main body part which includes the three axes- X, Y, and Z. The construction material varies based on the manufacturers. Recently, aluminum alloy or ceramics are the most used materials. Previously, steel and granite used to be applied.

Probing System

Without which a coordinate measuring tool is useless is the probing system. The probes directly contact the physical object and value various points based on the X, Y, and Z coordinates. Either they are operated by an operator or by a controlling system. It varies from machine to machine based on the structure of the machine, coordinating system, and requirements of measurements.

Controlling System

The control system is the controller of the final output of the points collected by the probes. It is considered the traffic officer of the whole system. The collected data are analyzed here for precision measurement and displayed on a computer interface by metrology software. This information is further analyzed by a regression algorithm.

Other Parts

Apart from the three major parts, a CMM has the following parts to complete its structure-

- Air Bearing

- Scales and Encodes

- Servo Motors

- Joysticks

Types of CMM

Before selecting a CMM, you must know about the four basic types of it. Although they all have three perpendicular axes- X, Y, and Z, they vary on the basis of their structures.

Bridge

The most common type of CMM is the bridge CMM. As they offer more accuracy at a low cost, they are the most popular as well. However, the bridge machine moves the probes to the three vertical axes and audits the probe position. With a repetitive process of measuring the surface location by sampling the sensors, it assures exactness in measuring the specs of the object.

Gantry

In terms of workmanship, gantry CMMs are pretty similar to bridge CMMs. For a safe and secure operation, a gantry machine can be directly mounted on the floor. They are much bigger in size, resultantly being engineered for measuring large components. We highly recommend having a gantry machine if your target is high accuracy with medium flexibility. You can count the smallest features without failure which is a big plus.

Cantilever

In the case of the Cantilever Coordinate Machine, small objects will be better at measuring samples as it is well-known for both precision and perfection. You will find the measuring head attached to only one side of the base. As it is relatively low in weight, you can move a Cantilever CMM pretty quickly.

Horizontal Arm

Want to measure the largest components possible? Then try it for sure. But there is a chance of less accuracy than the previous three CMMs. In a Horizontal Arm coordinate measuring machine, the X-axis along with the Z-axis(horizontal arm) are placed on a saddle. The saddle moves vertically though. Here, the Y-axis is considered as the long beam length. The components which are hard to reach for measurement are the primary target of this type of CMMs. For example, automotive sheet metal materials like car doors.

Basic Working Principle

Talking of the basic working practice, it basically follows a mechanical system to calculate an object’s geometry. The system moves probes to the three-dimensional axes to collect data. Then the software system enumerates the data to determine the size, shape, length, etc. of the object.

There is a reference position which is known as the standard position. The probe’s displacement from that particular point decides its location. A modern coordinate measuring machine even permits the system to control the probe for measuring usually unreachable surfaces. How interesting it is as a measuring device, isn’t it?

Having said that, a CMM works to test the range of the workpiece surface by analyzing the coordinates of the discrete points. Through the methodological mathematical calculations, it measures the best value for the product’s fitting as well.

Importance/ Application of Coordinate Measuring Machine

Now it’s time to heed to the application. You have learned about the technical part already. But what is the use of a CMM?

Well, it covers a widespread area. From irregular and complex calculation to realizing reverse engineering- a coordinate measuring device is all you can rely on. Even it works with the CNC(Computer Numerical Control) machine through information exchange. It does so to ensure quality control while manufacturing something.

Be it the automotive industry or molding, electronics or mechanical, furniture or tool- a CMM contributes everywhere for a precise measurement of the volume, length, conformity, and position tolerance of different machine accessories.

In the automotive sector, it plays a vital role in ensuring quality control. Consequently, it has a massive impact on the world economy too.

The four major benefits of this measurement device can be pointed this way-

- Fast and facile measurement

- Unfailing accuracy

- Compatibility in capturing complex calculations

- Saves time and money

How to Use It

To use a CMM correctly is a bit tricky. There are some specific factors you need to notice. Temperature is one of them. For meticulous measurement, the standard temperature is 68°F. Therefore, keep the target in the metrology lab way before measuring it- at least for five hours. Otherwise, there will be errors in the process and fervent flare will cause in-coordination.

The rest you need to do is to move the probes towards your targeted location. You can do it manually or with a controlling computer too. However, now the machine will mark the coordinates of the three axes repeatedly. Based on these records, the software will calculate the required dimensions of the object.

Point to be noted that to operate it you must have prior training. Usually, highly trained professionals handle these devices. Otherwise, the device could be damaged.

Closing Notes

Here comes the discussion on the coordinate measuring machine to an end. Hopefully, you have got the basic idea of CMM that how advanced workhorse it is to the recent industrial development. Any gigantic component with a complex geometry is inspected by a CMM for quality control. Buy a modern coordinate measuring machine and have your three-dimensional substance gauged unerringly.

Relevant Resources:

About This Writer

Hi, I am Eric Devin and I am a professional interior architect. Since childhood, I've always enjoyed DIY projects! And, I have loved to solve simple household problems using essential tools and equipment. I have also acquired a lot of information about basic household tools settings by working with contractors.