Do you know a dial indicator is an important device to measure in the industry or manufacturing company? Most of the new users are curious to know how it works. Some people are unaware of this tool.

In this article, we describe the dial indicator, its work process, advantages and disadvantages and other related factors. Hope this will fulfill your curious mind demands.

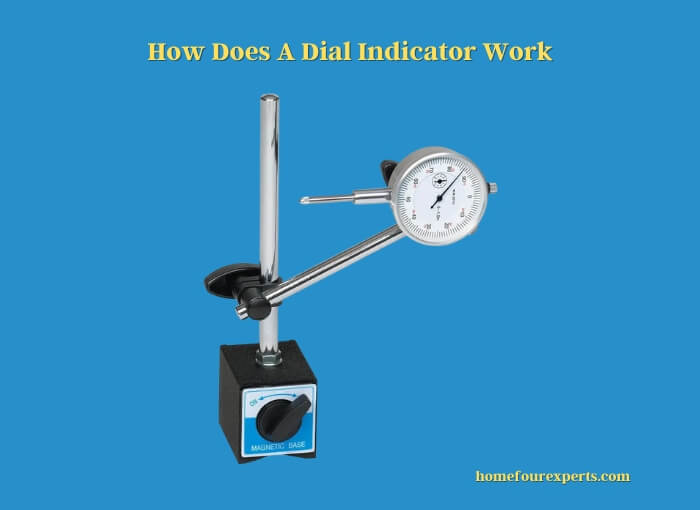

Dial Indicator

A dial indicator is a precision measuring instrument with jeweled or plain bearings, highly finished gears, pinions, and other precision parts. Measurements ranging from one-thousandth (0.001 inches or one mil) to 50 millionths of an inch are attainable.

Digital Indicator

A dial indicator or gauge is a measuring device that is used to determine linear displacement. Dial indicators are classified as dial gauges, where reading is done with the use of a clock, and digital gauges, where reading is done directly on an electronic digital indication, depending on the reading system.

How Does a Dial Indicator Works

If you want to know how a dial indicator works or its work process this section represents these factors. A dial indicator works on the premise of a system of gears and levers multiplying a very small upward pressure on the spindle at the contact point.

A dial finger is used to signify this on the dial’s face. Dial indicators body made with a round graduated dial and a contact point that is coupled to a spiral or gear train so that the amount of movement of the contact point is indicated by the hand on the dial face.

A spindle movement of 1 mm corresponds to this value. For protection, the instrument’s movement mechanism is contained within a metal housing. There are 100 divisions on the large dial scale. Slip gauges representing the basic dimensions of the part are used to zero the indicator.

Types of Dial Indicators

Different types of dial indicators are available in the market or online store. Users pick them according to the use and work projects. Here are some of them:

- Balance reading Dial Indicators;

- Reversed Balance Dial Indicators;

- Continuous Dial Indicators;

- Reverse continuous Dial Indicators;

- Prelinger Dial Indicators;

- Test Dial Indicators;

- Lever Dial Indicators.

Dial Indicators in Use

Engineers use dial indicators in a variety of ways, some of which are briefly listed below:

- In a machine, dial indicators are used to align a workpiece. Grinding machines, lathe machines, and milling machines are examples of EDM machines.

- The tools can also be used to check the spindle runout in a machine tool.

- Dial Indicators can be used to align workpieces in the spin fixture.

- It can also be used to determine the roughness of a surface.

- Injection molding parting lines are measured with dial indicators.

- Dial indicators are useful for determining the height difference on a surfer.

Positive Sites of Dial Indicator

Dial Indicators have several advantages or positive sites, including the following:

- In terms of linear measurements, a dial indicator is the most reliable tool.

- When it comes to ensuring the quality of a workpiece, this tool excels (Luo et al. 2018).

- Small tolerances allow for a very compact tool that can be used seamlessly in mass production because of its small size.

- In addition, dial indicators can be used for dimension control purposes.

- By aligning them with other attachments, dial indicators can also be used to measure several deviations.

- Dial Indicators can also be used to measure the amount of tapper without regard to roundness.

Negative Sites of Dial Indicator

A few drawbacks of dial indicators:

- Dial Indicators often lose precision due to vibrations from machinery.

- Due to space constraints, the tool may have to be installed at an angle, reducing the accuracy of the measuring device.

- The tool’s parallax effect is another major drawback.

- When it comes to dialing indicators, end floats can be a pain in the neck. There appears to be some axial play in journal bearings and sleeves. Because of this, Dial Indicators’ accuracy is affected.

FAQs

What Is the Working Principle of Dial Indicator?

The Dial Indicators’ functioning premise is that the movement of the spindle is multiplied by the reading of the main scale due to the needle’s indication. The rotation of pinions and gears is also represented on the main scale.

What Is the Function of Dial Indicator?

One of the most common measuring equipment used in precision engine building is dial indicators. Deck clearances, crankshaft thrust and straightness, lifter travel, and other measures involving the distance between two surfaces or modest amounts of component travel are common applications.

Conclusion

Through this article, we try to describe different aspects of the dial indicators. These devices play an important role in the industry. So it’s necessary to know about this device. Hope this article helps you a lot with the necessary information.

Featured image credit: Amazon.com

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.