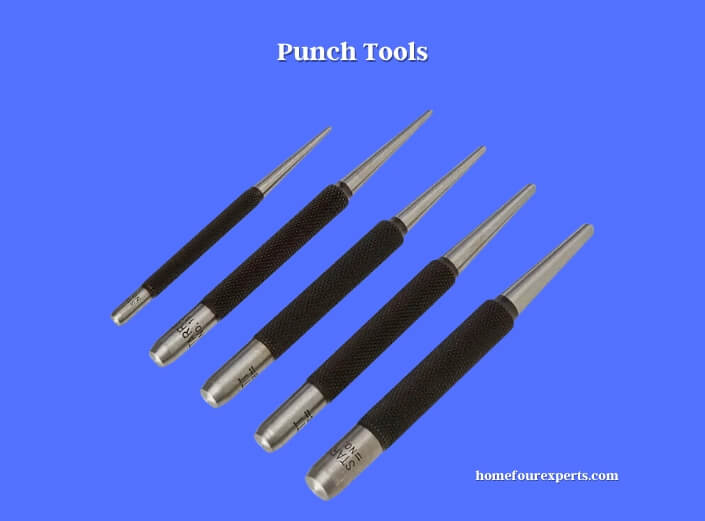

Familiar with punch tools? If you are a hobbyist for jewelry making, dyeing, printing on materials, letter punching on the desired motorcycle, or installing a belt coach on a common AR, then the answer is yes. Still, confused? Well, the definite punching tools used to press on extensive woodworking applications. Combined with other tools, for instance, hammers or mallets and chisels, these types of tools often work with precision for both cut-off and shaping wooden blocks and on similar hard or softer workpieces.

Being assisted with the pre-drilling mechanism, punch tools types and their uses vary, and you can add center, drift, prick, and other punches which we have enlisted in gradual sections. Even the pointer length and diameter sizes switch according to job purposes. However, after usage, the maintenance costs are separate. Users, especially novices, often ask how to open a punch.

More relevant questions may arise first as long as we have faced also. With different types of punch tool descriptions and their multiple usages, you will find the answers gradually.

What Is a Punch Tool?

Well, the answer lies in its design. A punching tool has a sharper pointed end while on the back side, it concludes a flat butt. So, the standard definition is it is a narrow, stiff, and small gadget for some scarecrow or for the professional’s sharp tip against a workpiece. Then the user can hit the flat end with the required mallet or hammer to cut the materials by the sharp end into 2 pieces.

As long as we have experienced, the sharp end differs as per the design and purposes that will be employed, and we have listed almost 12 punch tool sets to differentiate the customers’ needs by design.

Types of Punch Tools

In short as per the dictionary, punching means to hit something or someone with one’s fist or tools. Moreover, this type of punching tool is useful to cut off metal or hard workpieces into 2 or more pieces gradually. So, for your concern and without delay, let’s dive into the depth of the listed punching tools category with separate examples.

1. Center Punch

The first special punching tool features quite a smaller but heavy back-end blunter tip to an angle of 60 degrees and on the opposite end a sharp tip. There is an alternative design, but we will introduce it later on. You may ask where the specialty remains. Well, while working with a harder workpiece, it has that competency to create a shallow indentation for the drilling purpose. It means before drilling a precise hole, this device is useful to create the exact mark where the drill bit will enter.

Starrett S117PC Center Punch Set

Specifications

| Pieces | 5 |

| Material | Steel |

| Sizes | 1/16″, 5/64″, 3/32″, 1/8″, and 5/32″ |

| Weight | 6 pounds |

The first set of center punch tools we selected prior to the pre-drilling method. Well, this one is the well-known version of Starrett S117PC. Includes 5 shanks and each one comes with a wide range of assortment, for instance, 1/16″, 5/64″, 3/32″, 1/8″, and 5/32″ offset or tapered points.

The storage convenience is super like we have never enjoyed carrying from one site to another, and this is the red plastic lightweight one.

Each of the designed punches has hardened and tempered Stainless Steel in construction. Not only to prevent scratches but also to create non-breakable strength. Even recently the manufacturer has reinforced to create anti-corrosive features however the humidity is.

Hand-holding feature quality is damn awesome. Even while we have given trial, knurled round shanks performed as anti-slippery to create exact simple small dimple marks on the preferred object. So, invalid your scarecrow habit.

An internal spring mechanism has included a center automatic punch configuration as if to avoid the hammer application.

2. Prick Punch

A punching toolset of hard and tempered Carbon Steel, yet the exception relies on its making angle which is at a 30°. The purpose is almost common like the previous one but shorter for thick metal sheets gaping, creating holes, or ripping in the middle of the thinner materials.

Starrett 816A Prick Punch with Tapered Point Diameter

Specifications

| Pieces | 1 |

| Material | High Carbon Steel |

| Point size | 5/64″ |

| Item volume | 8 cubic inches |

To guide your thinner object, for instance, thin metal sheets for a pre-drilling process, Starrett 816A tapered prick punch is the special one. The exception we have still remembered because the 4” length and 5/64″ tapered point diameter become a starter dimple.

Speaking of the materials in this prick punch set construction, are similar to most of the solid punch tool sets, such as High Carbon Steel. However, the pointer is of hardened Steel and the shank is of tempered Steel whether you demand to wear resistance or non-breakable strength.

Even the pointer provides maximum precision for placement. Besides, the sturdy shank provides knurled grip to prevent slippery performance while giving a bigger shot after the minor ones if they do not work at all.

3. Solid Punch

Solid punch tools, are another variety of today’s topics that reloads the sturdiness to dispel materials from objects whether it is hard or soft. However, users can employ it for general driving components, such as pins, rivets, and more into workpieces again.

In general, this type is very common for sheet metal operations and boring holes in different measurements as per your job. While we have had a trial, we have noticed some techniques to use it in hot jobs, for instance, keep in cold water and cool them as long as possible for rough tasks.

Tekton 66071 Solid Punch Tool Set

Specifications

| Pieces | 1 |

| Material | High Carbon Steel |

| Point sizes | 1/16 – 3/8 inch |

| Weight | 1.5 pounds |

Aiming for a solid punching tool that is available in the stout and powerful model? Well, Tekton 66071 is a solid preference for you. Not only loosen up metallic object rusts but also frozen pins only by using a damage-free punch with permission to get driven inside.

One of the team members has had an alignment of ⅛ inch, which was small at ⅛ inch and with a large end of ⅜, and guess what? It worked in peace. You can apply it in the gas tube as if it is smaller than common pins, for instance, allowing it to be installed on a bolt catch for regular AR.

How about the material? If your purchase purpose is for bolt catch AR, then beware a little bit as if it can bend for higher pressure high Carbon Steel in construction. But yes, each punch size has been heated and treated individually for better and stronger tips while keeping the striking end.

4. Transfer Punch

Exceptional from the rest of the punch tools for standard length from production, 4” or a few more than that. The length is more than enough to move a hole location through a template or pattern on the material. But one thing is important to notice on the construction if you need a secure pre-drilled mark to create, and that is the non-tapered shape of a certain outer diameter.

However, it has great implications especially for DIYers or hobbyists, for instance, contraction of an actual hole’s tolerance, and if needed, transferring the whole center to another surface. Moreover, it is suitable for fixing tapping, or drilling holes in an object template to make a bolt.

Neiko 02621A Transfer Punch Set

Specifications

| Pieces | 28 |

| Material | Alloy Steel |

| Point size | 3/32″ to 1/2″ |

| Weight | 3.52 pounds |

The most powerful, yet hand-powered beast categorized transfer punching tools are in the demanding list 4th position. Ranging from 3/32″ to 0.5” punching tools diameter is a big deal to continue your tasks, such as separating holes, and creating or transferring pre-punched holes with the previous similar categorized gadget.

Neiko 02621A confirms punching capability with 64-graded High Tempered and heat-treated Alloy Steel to get in the insulation project while having a Black Oxide finish. Not only to eliminate the guesswork while transferring drilled or reamed holes and threads to make out through the hole.

Even perfect for stealing your scratches for an upper well-enough polished look. However, it is a better choice for pr machinists, engineers, and toolmakers to execute precise holes of a similar size whenever you require a single hit.

5. Drive Punch

Drive punch, is a standard punching tool that is worthy not only for its name but also for the convenience to pick up damaged or corrosive rivets, pins, and bolts from the surface you have drilled these in before. Its configuration shows a flat face instead of a point shape to drive out the materials by striking their endpoints.

Both sides of the manual device will taper the face. In fact, conditions are like punching the sharp V points, it will command employing a straight shank for precise hole outcomes.

Starrett S248 Drive Pin Punch Set

Specifications

| Pieces | 5 |

| Material | Steel |

| Sizes | 1/8″, 3/16″, 1/4″, 5/16″, 3/8″ |

| Point length | 8” |

Jumping to the next Starrett punching tool model. The S248 series has a straight metal pin drive on one end and on the opposite, another metal shank. That pin drive point has been tapped with a hammer.

Ranging each shanked gadget from 1/8″-3/8″ is a great reinforcement to insert pins or knock out rivets from the hole it is attached to. In general, the tempered heads are like other models that we have put in this listing to fracture from an off-center hard blow. We have also considered the finest, and that is extra length to execute the operation at ease, and possibly happened by the sturdy finger grip for controlling as well.

Unlike other models, the complete punch set comes in a red cardboard box.

6. Pin Punch

Though it is more likely to work as a drift or drive punch tool. The larger and more parallel one point, the more specifications of this device come in light. However, only for tight-fitting operations, this type is very helpful with the parallel end.

The tool works until the rivet or pin exits the hole it has inserted before.

Starrett S565WB Drive Pin Punch Tool Set

Specifications

| Pieces | 8 |

| Material | Steel |

| Point sizes | 1/16″, 3/32″, 1/8″, 5/32″, 3/16″, 7/32″, 1/4″, and 5/16″ |

| Point length | 4” |

The next and last Starret pin punch model is the S565WB series. Why have we chosen? In particular, one of the team members is a quality gunsmith machinist. Apart from the older models and their sizes, this 8 pieces of punching tools set has included less Chromium, Vanadium, and other raw materials, and better to spend bucks on the real Steel product.

Instead of those materials, Alloy Steel made devices, especially the normal tempered to higher tempered, often remain brighter and tend to be less prone to bending. Besides that, inscribed with a fractional diameter as well as the metric sizes which are very much accurate compared to other described models. But one thing just dragged us off the store and wished all pieces were a tad longer.

7. Roll Pin Punch

Sounds like a roller, right? Well, this category has a small projection in its center point to apprehend the threshold of the roll pin. In particular, for accelerating spring punches, as well as for the flat surface.

One feature one should ensure while applying this one is consistency parallel between the shank axis and the roll pin axis. Even users should not close the single side, otherwise, it may be unable to tolerate the hit and as a result, may bend the shank in terms of regular purposes.

Horusdy T97288 Roll Pin Punch Tool Set

Specifications

| Pieces | 9 |

| Material | Chrome-Vanadium Steel |

| Diameter | 1/16”, 5/64”, 3/32”, 1/8”, 5/32”, 3/16”, 7/32”, 1/4”, 5/16” |

| Length | 6” |

All new, yet the hardened, heat-treated, drop forged and in a single body roll pin punch tool set of 9 pieces from Horusdy T97288 is a great one. In general, the purpose of previous models is to hit workpieces with rounded tips, yet it contains neither the shape nor the original Steel in construction.

Being a mixture of Vanadium and Chromium which makes it more precise as a trendy punching tool set of 9 different pieces in a black handy pouch. Found it handier while the knurled grip provided a non-slippery facility, even without causing major harm. What else to include? Each member of our group, for instance, watchmakers building, engineers, carpenters, and jewelers found it useful and helpful to apply on machinery, guns, woodwork and crafts, vehicles, and unlimited things.

8. Hollow Punch

Apart from other hardened Steel punches, this punching tools type has hollowness inside for separating holes in metals, fabric, and cardboard. As if they have a hollow shape inside the center, different sizes in a set used to separate or cut the materials with them fall out through its built-in side grooves.

As long as we applied, it let us create a number of holes within seconds and many of us are using a similar thing without being affected by rust while the created holes are quite clear.

Mayhew Pro 66002 Imperial SAE Hollow Punch Set

Specifications

| Pieces | 27 |

| Material | Steel |

| Point length | 1/8-Inch to 2-Inch |

| Weight | 5.74 pounds |

| Measurement Unit | Imperial SAE |

The most unique one with a higher range and the heaviest one to get the jobs done by a single strike. Though we have found it as the most expensive one as per the quality and number of sizes. We have tried to produce customized gaskets. We have done this out of 1/9” thick red gasket rubber. And without struggling to get the punches for neat and clear cut, the task was accomplished.

Even if you want a try on a press, that must not be an issue to deal with, especially with the 5/16”. The applications give a good creation with 2 punches simultaneous usage and you can go for circle shape cutting.

9. Dot Punch

Similar to the center punch, yet this one is larger than that and approximately the pointer has to face at a 60° angle. If you are thinking of creating permanent marking by scribes as if it has been done through the digital height gauge for not allowing the lines to change at working time.

Basically, it saves time and energy if you draw the marking on the exact point as per your desire. In general, the length ranges from 80 mm to 100 mm and thickness you guess? Around 3mm to 5mm.

Tech-P Circle Dots Craft Punch

Specifications

| Pieces | 4 |

| Material | ABS + Alloy |

| Sizes | 5/8″, 1″, 1.5″, 2″ |

| Design | Circle |

Another exceptional punch tool set is worthy of 2 separate designs apart from its name. However, to achieve better paper cutting, use a paper layered thickness of less than 2mm, yet the punch pattern is almost the same as the other models.

Our friend, a crafter, has got the ultimate satisfaction from the very new punching model from Tech-P. In fact, the blade cover is too hard not to tear off. You can use the diameters in this case, for instance, 5/8″ for ripping circle shapes, as long as the 1” and 1.5” are similar, but 2” is only for paper punching in a simple way. Overall, its embossed design and pattern are great for foil and Eva foams too.

10. Bell Punch

As per its name, it is designed to symbolize a small bell or horn. Either for the lightest marking or to unearth the round jobs center point, this type of punching tool is a great invention.

Spring has been attached out of the factory and fixed with a punch, also known as a center punch. Users only require to use the flat end with a hammer. However, because of the in-built spring punch, it will rise along.

Engineer’s Bell Punch Tool

Specifications

| Pieces | 1 |

| Material | Steel |

| Size | Upto 38 mm |

The oldest model from Global Tool in our punching tools listing. In general, the bell resembles the shape and punching pattern. This handy model prefers to serve as a center-finding tool to search for round bars up to 35 mm.

The satisfactional matter is, the whole metal is made of EN31 Alloy Steel which will perform for longer without causing damage. In short, no efforts need to give a short punch to make the task done.

However, we had a project aiming for a rod center with 1″ 1/1/2″, and it did not disappoint us.

11. Letter Punch

Worth a letter stamp. As per its name, the form is a type of reverse image where you can see the back flat (not that much) first in the box of the punching tools set and similar on the punching end. As a result, the final results seem to be quickly readable more than showing something positive.

Such a number of high-end letter stamps help you convert the letter prints and often the numbers in block size over a workpiece. For example, special usage or you can say indispensable for mold making and dyeing.

Tekton 6610 Letter and Number Stamp Set

Specifications

| Pieces | 36 |

| Material | Alloy Steel |

| Sizes | 5/32-Inch |

| Punch width | 1/4 inch |

| Punch length | 2-3/8 inch |

Well, we (team members) admit that the fractions are not suitable for us that much, yet it worked well for washer stamping as if they are not hardened enough, and still worked on 8-graded washer stamping. But the backstop is right now important like the rest of the back ends.

However, this Alloy Steel made punching tool set of 36 pieces may work well if you give high pressure for creating stamps on concrete materials like floors or heavy desks. In that case, you will require a beast seasonal full-sized hammer.

Conclude the black carrier box with 9 number boxes and from A-Z letter stamps for quick identification and selection, however, the number stamps are a bit uneven in height measurement.

12. Automatic Punch

Last but the most individuality carrying gadget among the rest of the punching tools that we have ever enjoyed before. As per its name, invalid the application for a bigger and full-sized hammer for automatically accomplishing the heaviest punching jobs.

Almost all manufacturers have integrated an automated keypunch in its body with a strong spring which is also made of High Carbon Steel. A lever head permits the spring to remain settled through it. The lever head gets pressed by the user when your marking has been done. This automated pressure which is built at a 60° or 90° angle will get done.

Neiko 02638A Automatic Center Hole Punch Tool

Specifications

| Pieces | 1 |

| Material | S2 Steel |

| Point length | 5” |

Last but not least, however, we have mentioned that Neiko 02638A is automated to accommodate various materials from hard ones to softer ones in an automatic way and takes a maximum single damn minute.

To type an adjustable stroke, a 5” center punch will lever up spring loads. The chrome-plated shank has been built as a single forged and reinforced with Carbon Steel to withstand high-impact forces while dealing with hard surfaces and to serve them with a single drill punch. You can even thank the reinforced S2 Steel tips. However, this spring load takes the job easier by contracting or expanding the force as per your press.

Whether needed for a glass window breaker or for an awl for belts, its precision-centered tip is all alone enough.

How to Select Punch Tools Set?

Precautions

What punching tools are applied for? More than that, it required precision and correction to make any single punch. Before proceeding to purchase a better set, take a glance at the precautions of using the punching tools set.

Select whether the materials are softer or harder, for instance, foam, or paper to concrete floors.

Never try to employ common punches, yet in the case of automatic punching tools, for instance, Neiko 02638A, invalid the hammer introduction.

Watch its angle as per the workpiece size.

Repair the damaged punching point and make it sharp to create an accurate hole.

Hollow punches are not eligible for thick sheets. So use any Engineer’s Bell Punch Tool instead.

Length

Varying in reliability on the strength, punch tools vary in lengths too, in fact, a few models have been designed in the longer form to get through the harder tools, for example, Horusdy T97288 with a 6” length pinpoint to make the task done within seconds. Though instead of punch tools, there remain versatile chisels of Steel with reinforced features to handle your materials dividing jobs. However, punch tools’ lengths create common differences, for example, useful for both object separation and making holes.

Shape to Purpose

This is about the shape and obviously, the angles at it have been built. Most of the punch tools come with 60 degrees, 90 degrees, or less than both of the angled degrees. Even as a professional user, you may get bored by making changes frequently to the pits. The gadgets may discharge no burr and indentation to make the holes neat and clean.

Here also complete a material consideration. As much as the metallic construction, the features included were too high to get the jobs done. However, we have experienced a wide range of metallic versions, S2 Steel tips, High Carbon Steel, Alloy Steel including Chromium and Vanadium mixture, Spring Steel and ABS. So, you better check personal necessities first at home.

People Also Asked

Can I FInd a Pin Replacement?

Well, the answer is yes, including the repair jobs. Any hobbyist store is the perfect finding for your preferred jobs to get done.

Can You Use It on Aluminum Goods?

You may, but already we have mentioned everything has not been produced for everything. So, it is worth listing out the materials that you will be applying.

The Idea of Starting Punch Guarantee?

This is a synonym of drift punch, except for the body shape, and comes within a particular shorter and wider point. Calls for the first implications and before using any pin punches like a pro. Acts like a pro prior to knocking out pins and rivets from frozen objects.

Final Words

In practice, you want to employ a drive punch, yet the pin or rivets are too hard to execute the operations. Otherwise, want a trial with pin or hollow, or center punch tools? Confused, right? Till you decide, give a first with our ready-made breakthrough of info regarding punch tools and their separate uses to choose the correct one, even with details.

So, we hope to see and hear your punching experiences. Oops! Not on the face, but on the desired materials to fit a drill-locating hole.

Read more:

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.