Remember the ancient architecture level of Egyptians through their pyramid structure creation, specially the Noah built an ark in cubits. They measured the stone of each pyramid as the distance ranging from elbow to fingertips. So, from ancient times, measuring tools are inevitable in our regular mechanism creation and maintenance of the project.

As the first choice first need, specially in the case of engineering, multipurpose or separate tools are important to store in your bucket listing. Moreover, from temperature measurement to glucose detection, there are multi-tools to work alone.

We have summarized measuring tools listing that need in your workshop, even gradually have provided a second overview to help to purchase one. In each measurement device summary, you will get a short definition of each and functional characteristic, in addition, to operate your project alone. Please give a thorough reading and happy measuring tasks.

What Are Measuring Tools?

Accuracy and simplicity, the most prior characteristics that each tool maintains while intending to provide long-term services not only in metalworking but also in woodworking too.

Before stepping forward have you checked out the pieces you took in terms of sizes, lengths, angles, shapes, corners, and more. Overall instructions inside the instrument’s box may not be included to motorize your jobs. In this case, measuring tools acknowledgment, specially those devices which are popular from the beginning of your carpentry or metalworking career till the establishment of your workshop, and further for bigger task alignment.

Therefore, physical instruments whether it is manual or a digital form give the proper reading through physical quantity to accomplish your further tasks. Simple measuring tools are not that much sense in terms of materials in constructions and shapes.

If it is about the most sensitive and regularly required ones, for instance, angle plate bore gauge, glucometer, square block, and more, then your first priority is to dive into this device acknowledgment.

Different Types of Measuring Tools Need in Your Workshop

Step back in time and imagine, what is happening without different measuring and detecting devices? To invalid such a nightmare, we have brought down a wide range of tools and from our real experiences as each will aid your workshop projects.

1. Bore Gauge

First experienced and even the best measuring tool variety we need in our workshop. This toolkit is typically good for measuring different dimensions and bore once we have inserted it inside the bore or measuring object, an automatic anvil expanding mechanism worked out as per the depth of the bore.

In terms of determining the radius of the hole, and including this test, you can perform other tests too, for instance, cylinder test, bore mics, hold bore gauges, and internal micrometer. But before purchasing this handy and mid-sized gadget, select the purpose precisely so that you may not have that much trouble continuing testing with it.

As well as the variety of bore gauges and their availability relies often on their accessibility and digitalization. For example, small hole gauges, telescopic gauges, Beam gauges, dial bore gauges, and inside micrometers.

2. Laser Measure

With the digitalization and by the passage of time, most of the devices have been manufactured to follow the instructions of users digitally by using AI or Artificial Intelligence. As well as the modernization and invention, laser measure is an alternative to a manual measuring tape, not only to measure a space length but also to provide precision for your next project.

At the single tap of its integrated button on its laser beam, it is capable enough to hit your desired target. Also, from the very distinct destination, it can reflect on that thing without any measurement issues.

This is quite different from metal tape, not only in terms of applications but also in its integration with digital parts. For example, it can simply measure like the walking distance without holding like a manual metal measure tape, in fact, the entire machine can put up to accuracies to account for tape sages.

However, this is important for the device to measure off the angles, which even causes discrepancies. Featuring more than 650feet distance measuring quality with precision, even from an angle of about 300feet.

With boasting performance, the manual model provides accuracy within an 8th of an inch. In particular, an ideal and practical measurement you can go through with confined places or angles measurements, for instance, tall ceilings., yet this model needs to press a button targeting the point to cover up the reading whether the environment has enough light or not.

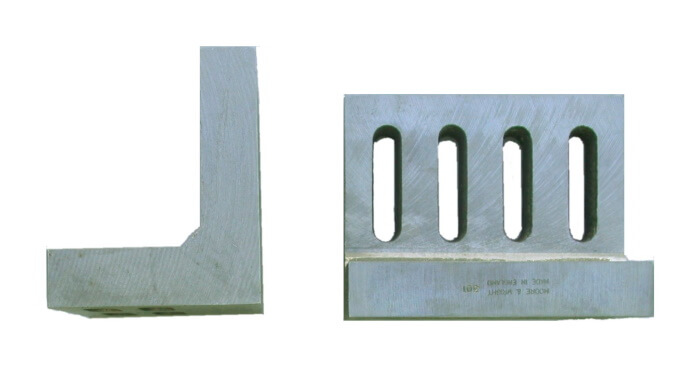

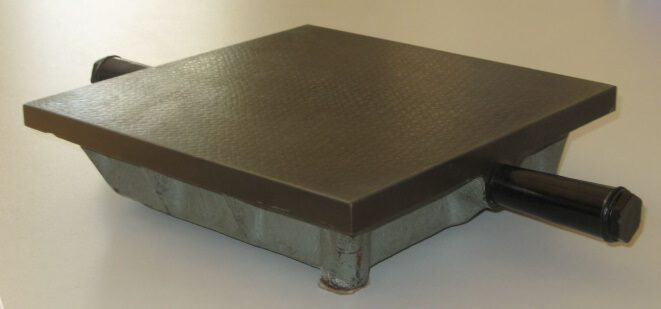

3. Plate

Like a blacksmith tong, an angle plate also works as a holding device to fit any type of metalworking and woodworking evenly. All of the angle plate models you purchase have premium spheroidal Cast Iron in their construction to ensure the highest rigidity of the equipment stabilizes and no replacement or distortion between the mechanism and separate parts of making an object.

Available in 2 categories, whether one comprises adjustability, and another one has a fixed mechanism in its construction. An adjustable angle plate splits from a fixed model in terms of the adjusting method. While the adjustable mechanism featuring the model can fit any size of applications near to its range, yet the fixed one fits a few applications. However, the adjusting model has an adjusting knob to fix the plate to the material you are using to place it in its positive position.

In general, both angle plate varieties are beneficial to secure object grasping while the user goes for marking out a wide range of points, even feasible to shape as per designs and cutting.

4. Calipers

Increasing popularity in today’s engineering world. Students find it in their physics and similar subject labs to include different linear measurements in each scale, for instance, width, measuring lengths, the diameter of holes, and depth of holes. Not every caliper but almost all models have a resolution down to earth and ranging from 0.01 mm (0.0005″), pretty much significant, accurate and straightforward.

Next to your roadside stores, a wide range of calipers according to valid purposes are available, for instance, vernier, digital, dial, inside, outside, divider, oddleg, and micrometer models. But popular to students are only the vernier, dial, and digital calipers models to satisfy their lab demand and enhance basic measuring tools knowledge.

Among these caliper models, both dial and digital calipers provide quick reading rather than other determining caliper models, however, consume power through battery or electricity. But the best transparent reading both provide not only for being used to modern LCD but also continuing a digital and precise reading for your tasks.

Vernier caliper is a moving scale that is generally used to determine object values in decimal units after the real deal. It may have zero error at the utmost level of some physical properties, for instance, compression and expansion, rusting, external damage, and more. In terms of avoiding external damage, yet it if happens then follow the below determination formula:

actual reading = main scale reading + vernier scale reading ± zero error

5. Center Gauge

What is a center gauge, any guess? Well, this must-have lightweight measuring tool in your workshop not only benefits your lathe work operations but also for setting threads at their places. Both fishtail and center gauges determine the angle at where and when the grinding should take place for the object’s profile.

As well as the center gauge has been designed for material grinding and setting its thread cutting tools, especially the hand grinding solution, which consists of Stainless Steel to perform with strong withstanding power.

However, center gauges top-notch finishing style comes from Satin Chrome which is a rare finding in other workshop needed measuring tool constructions. Along with 2 separate item codes, while ABM-EPT-9305 is standard for 55° whit, another ABM-EPT=9306 is worth measuring for a 60° US system.

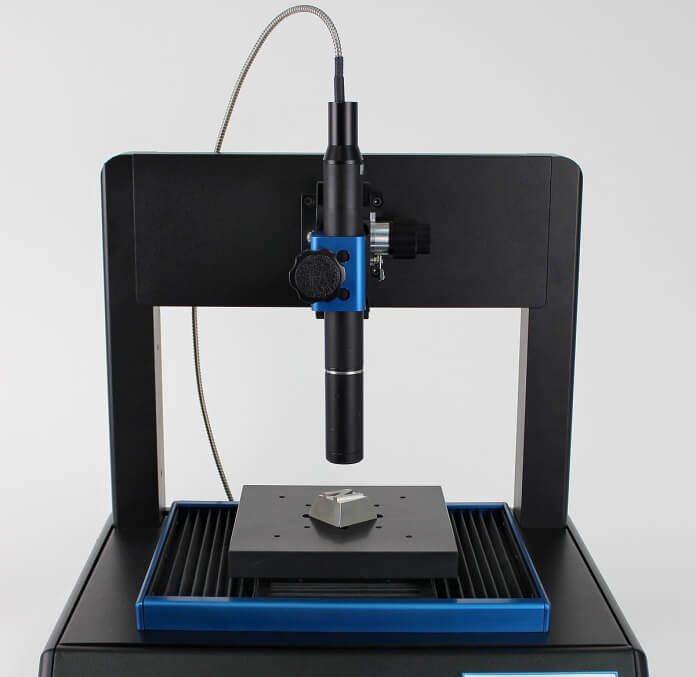

6. Coordinate Measuring Machine

CMM or a Coordinate Measuring Machine comes with 3 main counterparts, such as mechanical probe or probing system, the main structure, and data collection and dispatch mechanism. Almost all CM machines are obliged to follow the basic measurement system of the 10360 series.

However, this measuring device is fruitful in locating physical objects’ geometry, especially with its main probing mechanism. Its entire structure is full of ultra sensor systems, for instance, laser, optical and white light. Utilizing each of the sensing types typically relies on a material’s position if it is in a 3-dimensional Cartesian Coordinate system, for instance, XYZ axes.

7. Combination Square

Another measuring tool is needed in your workshop and almost its head part matches with the blacksmith project idea accomplishment required anvil. However, all along it comes with dual main parts, one is the earlier mentioned head and another is the ruler.

Similar to an anvil, its head has multiple structures relying on craftsman’s requirement and as per the designer. However, it is applicable in 2 different angles, like a square for 45° and 90°, but surface checking should be the first concern before employing this square device.

What about its ruler? Well, a ruler is another vital counterpart to moving rail in its construction, and yes, helps the head to move around the object even with a forward and backward direction mechanism. The ruler has in-built either imperial or metric and both measurement systems. Among the available combination square rulers, bigger ones in-built construction ranges up to 24” or 600mm and smaller ones up to 4” or 150mm approximately.

8. Drawbar Force Gauge

Isn’t force itself an emergency physical quantity? By maintaining the force in a machine like a drawbar gauge grows the feasibility to measure the exact force or PSI of other machines to determine and maintain the pressure of air to continue with the tool. Its basic work is to help to maximize or to minimize forces to invalidate every wrong incident from happening.

It is common that present trendy and modern devices, for instance, chainsaws are also running by consuming airpower with the hose with a maximum of 5000 Newton forces. Drawbar gauge consists of a dial indicator that the user can easily observe and maintain the pressure of his machine. Moreover, the dial is available in both digital and manual dial forms relying on machine digitalization.

9. Cylindrical-coordinate Measuring Machine

Similar to CMM, CCMM or Cylindrical-coordinate Measuring Machine takes down the earth for fitting cylindrical-shaped object’s position while the CMM is not that capable in this case. This measuring heavy-duty device is perfect for the crankshaft, camshaft, transmission shafts, and the rest of the wide range of rotating parts. This measuring machine also follows the standard ISO 10360.

With an in-built moving table that is relative to the probe for rotating the machine’s head part. However, its probe mechanism or counterpart can move the neck, particularly in the “Z” direction by omitting both X and Y axes. In contrast, the opposite axes can be missed while X and Y rotation maneuverability is open.

10. Feeler Gauge

A feeler gauge is a comparable design with the Japanese traditional handy fans. As per its name, measure the gaps of angles with precision until you turn each of the blades or leaves. Specially the gap between sides or shafts is the main motto of this device to measure and keep you accurate readings. Apart from the shaft or sides gap measurement and reading providing, applicable to metalworking to remove invisibility between 2 parts.

For easier tasking between gaps, firstly take the reading of the length of the component, then set the blade of one of the feeler gauges to continue reading. Feeler gauges come in a set with versatile thickness, even different as per the materials in construction.

In general, basic and traditional models of feeler gauge sets have Stainless Steel or Satin Chrome in their construction. Not only the construction materials have been utilized for withstanding and boasting performance but also to create readings with enough thickness.

Fortunately, in terms of shapes, 2 types of feeler gauges are available here in the super shops, such as parallel and tapered formed ones. And the talk of the topic, its reading units are available both in imperial and metric or we can say English Unit measurement scale to approach on the worldwide material surface to take their valid thickness.

11. Ruler

The second name, rule, and standard as a line gauge or a quintessential measuring toolkit. Ruler is a common measuring tool, even you can say one of the basic measuring tools needed in your workshop.

A simple premise you can check, it is eventually easy for preschoolers who only have their depot in their pencil box. Those pencil box depots featuring tools are useful only for measuring a short distance just like your hand or a foot length.

Moreover, applicable in preschoolers drawing competitions, short lab tools measurement, and similar tasks to aid in drawing straight lines for geometrical purposes. In the engineering world, mostly for architecture while designing a construction building, a restaurant, or a roadway to build something that you want to live in or start a new business.

Its construction is no longer split from other tools, for instance, wood, metal, and plastic. Professionals, as we have mentioned the architecture and civil engineers, infer to large dimensional ones to determine the longest things. However, metal rulers have the best durability in their offer, yet these are too expensive at present. But the utmost standard sizes can vary from 6” or 15mm or 12” and 16” or 30cm or more than that.

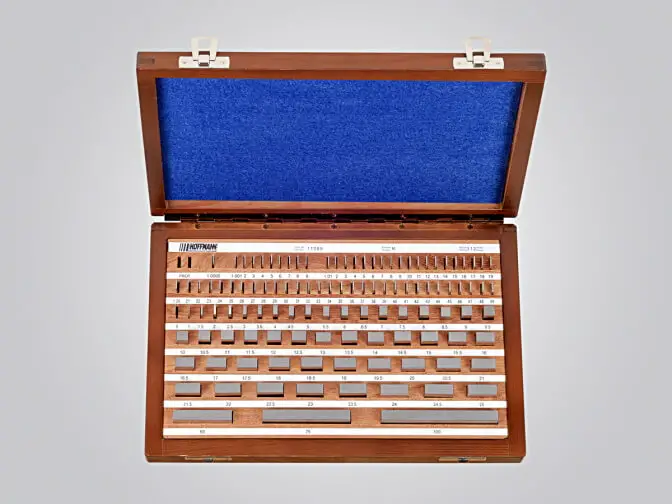

12. Gauge Block

Every tool’s counterparts and mechanisms are non-breakable and promising, if you are holding this aspect, it is nothing more than living in a fool’s world. Apart from the standardization of those tools, it needs to get repaired after providing a longer service.

It is a gauge block, not only supported to repair tools by consisting of a set but also to produce precision lengths. The materials in its making site are used, Chromium Carbide, Ceramic, Tungsten Carbide and more relevant to this.

When we have applied a gauge block, it requires itself to gently put the block set out and clean with sorted lubricating oil or Petroleum Jelly. At 20°C, we have determined and experienced the most calibrating power, yet it depends on the approximate thermal expansion that may provide additional tolerances. Thus it suggests the utmost calibration at this temperature.

13. Dial Indicator

Available and a bucks-worthy tool in both metal and wooden pieces and mostly found in woodworking places. What does it measure? Well, it has been designed for precise surface flatness, shape, roundness, and run-out tolerances. However, depending on the exact placement of the object’s surface. A linear movement into an indicator’s circular movement is feasible with the gear transfer.

A dial indicator you can set or install at the bore gauge top place where the readout you can watch perfectly. Then a visual reading you can observe to measure the surface weight and flatness, shape, and more identification terms.

Based on this tool’s mechanism, it varies into different categories, for instance, continuous, balanced, reverse, revered, plunger, dial test, and lever dial. Though dial indicators are safe to use for precise flatness measurement, the feasibility to improve the measuring tools, and integration with other tools, we bet neither to find a better indicator than this form.

14. Height Gauge

Though we have mentioned earlier that a gauge block is useful to take the reading of length of any object, what about material’s height measurement? Well, this device is only for its name purpose.

A height gauge is a typical tool to employ its sharp pointer like a dial indicator to measure the exact position of the object you are aiming for. If you have observed in the hospital how the doctor or compounder used to give therapy to the patient according to their height, then you have practical and basic knowledge of how to align with the height gauge.

However, the entire height gauge has a datum optimized by the scriber underside for the ultimate optimization. But at first purchase, it was quite overwhelming with the optimization terms, for instance, both height and surface gauge come with similar looks as if the designer might have forgotten to create a separate characterized device.

Yet that overwhelming mismatch, a height gauge has a bar or pointer head, in contrast, a surface gauge has no head except for a scriber point.

15. Marking Gauge

A very popular handy-designed device in the engineer’s world. Even in most of the woodworker or metalworkers workshops, a marking gauge is noticeable on your first spot. Commonly comes with precision in a parallel alignment to the inferred edge or surface.

It is pretty much similar to a preschooler’s compass to be an aid to their drawing. From the pointer integration on the headstock aspect, we can put the pointer in the fixed corner or on the surface and mark the calculator endpoint with the pencil in its other hole like a compass.

As well as with marking the required aligned surface places, assigned to mark the outline for metal or wood cutting purposes. We should brief the aligned device structure for your better task accomplishment.

Consisting of 3 regions, such as early mentioned headstock, lever or a wedge, and a beam. Instead of a pen or pencil holding a compass for applying on paper, a marking gauge offers a knife and it may vary as a panel gauge and mortise gauge.

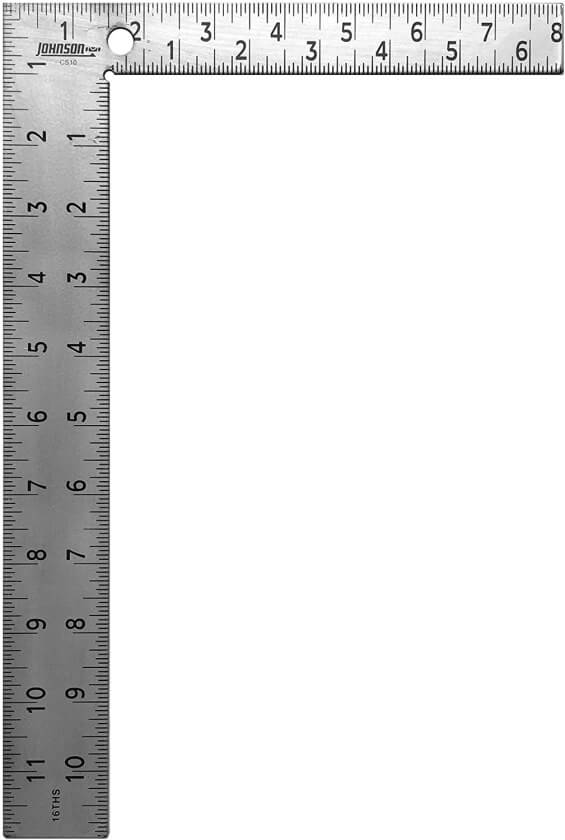

16. Machinist Square

This one is also an eye-catching woodworking and metalworking instrument. Also, popular as engineer’s square too which has a Stainless Steel blade welded into a heavy-duty body at an angle of 90°.

On its Stainless Steel surface, its imperial and digital digits bring perfect linear measurement. In contrast, a machinist can not only align its heavier body but also the prime body to determine the required counterparts according to overall angle and length.

0.0002 inches in its per length error is a machinist square for any precision instrument, yet this is acceptable. For regular reading purposes, this square is very useful.

17. Profilometer

It is a computerized machine, which determines the surface roughness. Solving variance issues, such as curvature, step, and flatness, prospective users can find its roughness although. A profilometer is available in basic 2 different types, phase-shifting interferometry, and digital holographic microscopy. The rest of the interface contrast microscopy models are vertical scanning interferometry and similar types.

However, in almost all Bachelor in Engineering degree holders and during Bachelor times, students have this device to determine an object’s roughness or its surface roughness to consolidate the price of the task and time as well. But before that, utilizing acknowledgment is the priority.

Based on other factors, you can classify this tool into other categories, you can keep trying with the non-contact profilometers, fiber-based, time-resolved, and more.

18. Optical Comparator

Are you done with your engineering? Not a big deal if you are not. Well, you might have familiarity with engineering drawing, yet your working principle acknowledgment is the inevitable one. Users can optimize this tool to determine an object’s dimension.

Great integration with a magnifying glass that is capable of reflecting the projected beam to generate a 2-dimensional sketch. Its principle of optics is far better to inspect the two-dimensional project.

Optical comparators include projection methods, inverted screen sizes, positive or inverted images, magnification, accessories, and worktables. Rather than other machines for the metalworking, this one charges too much.

19. Radius Gauge

Similar to the previous machine, this instrument has Stainless Steel in its construction. Mostly popular as a fillet gauge. Consists of both convex and concave sections of the blade in the one set of radius gauge. By the way, it has separate types and mostly in 2, one is external and another is internal. First, fix your position, then step forward to purchase one of the types to work conveniently.

Such a metalworking measure-taking tool has the main obligation to determine an object’s radius, except for the precision expectation you should invalid in the darkness and from the object’s behind. Moreover, never forget to place the material in the right condition.

20. Snap Gauge

Suppose, you have taken 2 adjacent parts of metal and are thinking of joining them together. How will you? Well, snap gauge is the bucks’ worth solution, in this case, to tolerate and fit in the ultimate position, however, it is also popular in go/no-go gauges in engineers and hobbyists fields.

Comes in a C shape to adjust the parts with an indicator on its head part. Simply like other measuring devices, there is a nearly to zero limit of verification to bring a perfect match to a present dimensional point with predefined tolerances.

Moreover, a snap gauge’s surface is pretty similar to an anvil’s, even made of a high-quality Tungsten Carbide blade for creating wear resistance. Though a snap gauge is small in structure rather than an anvil, helps in significant metallic item building jobs.

21. Sine Bar

We all engineers are familiar with a sine trigonometric function rather than its name as a sine bar. As well as for its in-built special function, get the metal jobs quite fast, eventually with the practice within a few minutes.

In online or offline markets, mostly 2 or 3 types are available. As per our experience, these 3 types are better to deal with, such as compound sine table, sine center, and sine table. Based on different functionalities, and as per your concern to fit your applications, these basic sine competent acknowledgment is better.

Including sine bar’s basic types, a sine bar’s structure is rather not complicated as if 2 cylinders at the key bar’s end. If you have found 3-cylindrical holes, then firstly place your sine bar on a specific hole and simply apply the sine law to determine an item angle.

22. Square (Tool)

As we have mentioned about the confusion about determining whether to use a square (tool) or a machinist square in metalworking measuring toolkits. As well as for marking purposes, both simple and handy devices are popular.

For referencing to build angles at 90° and 45°, however, similar marking tools are available at present everywhere, for instance, combination square, center square, machinist square, a cylindrical square which we have already mentioned.

Consequently, in terms of functionality, the structural differences indicate that the pre-attached billet in a machinist square is made of metal or wood, in contrast, the Aluminum billet is in the square building. However, the adaptation depends on your manual skill and practice with the jobs.

23. Surface Plate

You have assembled a machine and got the jobs done. It is time to disassemble the properly aligned machined parts, but an accurate alignment is better vital to you. If you are a prospective user rather than a professional person, it is better to get acknowledged that a single mistake can bring damage to your hundred dollars worth of machine.

This tool is a solution to assist not only in disassembling machined parts but also to keep the baseline as per the machine alignment to make sure that the counterparts have avoided the flatness of the surface or not.

However, the surface plates are flat-shaped in common usage. Its extreme flatness with withstanding power is outstanding which is lower than 0.0115mm. The materials used in its base construction are cast Iron, Steel, granite, and sometimes hardened Glass. Top to bottom consists of 250mm x 250mm in size dimension and is very much effective on both metal and hardwood.

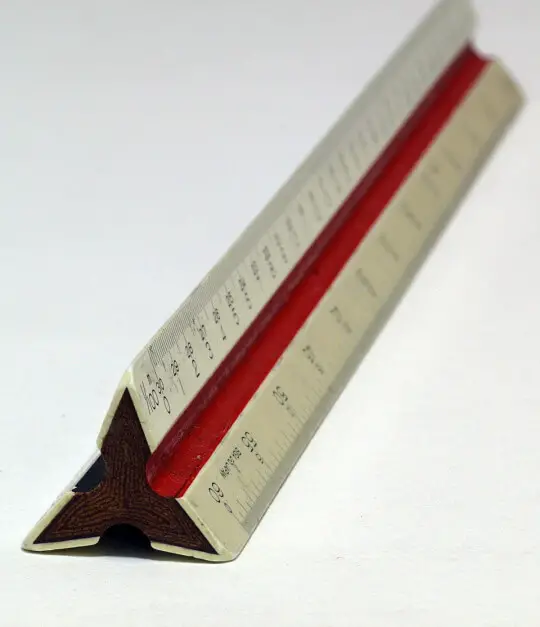

24. Straightedge

It is a far more complicated tool in the engineering world. Moreover, it has a critical tolerance feature in terms of interchangeability, as well as indicating the highest level of benefits while employing it on other materials. Like a ruler, assist in drawing to keep up with straight lines and features better checkout points for straightness.

A constant triangular shape along with 3-sides measurement digits while it has a red circular drain in its mid-point. However, more than regular Bachelor’s degree optimizing students, have widespread popularity for tasking in the automobile workshops.

Not only it brings a perfect match to the surfaces but also check out the exact flatnesses of that item’s surface. Nothing can cause external damage to its body, yet you should always be concerned about the superior applications with hard-to-hand.

25. Tape Measure

A regular purposive toolkit for everyone, for instance, a carpenter, a metal worker, a woodworker, and so on. It comes in a long and thin flexible shape depicted inside a turner as if you press the button or stretch out the head of the ruler, it should come out at ease. In general, it is used to measure different item’s lengths and sizes to help in optimizing your jobs.

In search of the tape measure, you will find 2 basic models with different materials in-built, such as plastic flexible and self-retracting metal formed. From workshop to industry and mostly in versatile manufacturing places, this tape measure is noticeable.

What about its limits of application. Unlike other manual tools, this one has zero limitation, though an error you may find in its length which is about up to 100m. However, recent research has indicated check graduation ranging between 1/32-inches. Yet to determine accuracy, 3 different levels are predictable in every 10m.

Class-1: ±1.10 mm;

Class-2: ±2.30 mm;

Class-3: ±4.60 mm.

26. Wiggler Tool

Rather than being simple, far more complicated measuring devices. In particular, it does not come in a single instrument package. As well as from the manufacturer’s factory, even the names are based on versatile applications, such as laser centering device, edge finder, wobbler, and center finder. The main version of this device locates the alignment of a machine with the work.

27. Thread Pitch Gauge

The original version of a thread pitch gauge is similar to multiple metal plates in a single set attached with a nut. Though each of them has separate standards which often vary as per manufacturer and workers’ workshop requirements. It not only helps in determining the thread pitch but also determines the tapered holes or thread on a screw.

We all know that screws and nuts are complementary in terms of mechanical joints. Like other tools usage procedures, you should know how and where it fits according to the size. But before that, no jumping into the machining. Well, in terms of good acknowledgment of mechanical joints, the thread pitch gauge is a very good measurement tool for the lead of a screw thread.

28. Tailor’s Measuring Tape

While a tape measure depot inside a tool fixer with retractable switch, yet a tailor’s measuring tape is considered as the simplest one to handle tailor’s tailoring jobs precisely. Due to its simple construction, it has also been standardized to perform in a single hand. Rather than an engineer measuring tape, this is better flexible and has in-built softer materials to conclude your points of the job.

Both starting and ending points are metallic and the storage tailor can keep them in a plastic case. If its manufacturing is based on cotton fabric materials, then it is much gentler against the user’s skin.

Often it is available in a plastic coating like an engineer’s tape measure to open and get the jobs at ease. Also, while taking measurements of a body for tailoring a person’s dress, the tailor can take it to easily align around the body curves of that person. However, if it has plastic cases, of course, an integrated switch must be there to open the tape.

29. Level

Do you know the bubble level or the spirit level? Yes, those are level synonyms and in general, users can employ a level on measuring whether the object angle is in an equal and balanced position or not. If you are working in carpentry or construction, for example, fitting hanging mirrors or frames on home walls.

Features a different level in sizes, such as handy and short versions, yard-long versions, and more either for small tasks or bigger backyard jobs. It can drive through the mirror vials which may fix into the level, yet filled with color and liquid spirit is necessary too. The spirit is necessary to fill the vial blanks within minutes.

How to operate? Well, at first take a level and simply fit it on the item top point to uplift the level, and try to adjust until those existing bubbles get settled inside the mirror vails. This measuring tool is an absolute solution for taking the reading of vertical and horizontal levels. Therefore, plumb tasks refer to it.

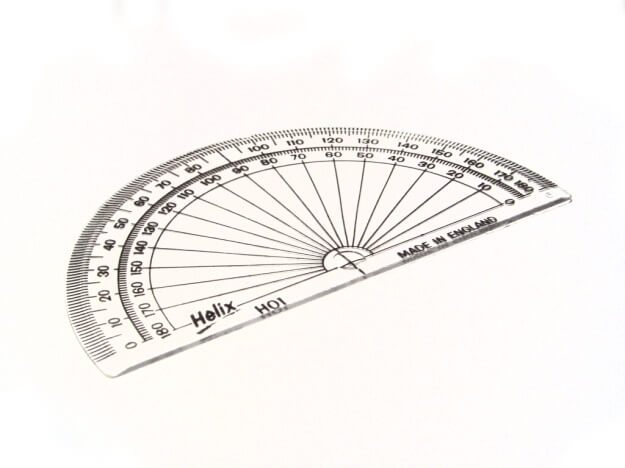

30. Protractor

Preschoolers are better familiar with this measuring tool rather than noticing in workshops. In general, this typical tool used geometry, mathematical terms, and hypotheses aid to drawing, and measuring angles. Not only is it an aid to solve complex determinations but also makes it easy to grasp to the students.

Enough convenient for physicists and scientists usage, even these are in plastic for being lightweight. However, these are valuable whether these are available in metal construction, and other academic pursuits too.

31. Measuring Cups

This one should not be skipped, why? Because a full set of measuring cups, defining various sizes, lengths, materials, and other culinary purposive features. Moreover, one set of measurement cups after purchasing gives a long-time service by not only bringing charms in your kitchen but also be used to measure chemicals to generate something more and evaluate the formula in chemist labs.

Regardless of the ideas behind measurement, it is not a big deal to collaborate with the approximate purposes. Moreover, how many cups of flour you are pouring for cake baking matters, so you want it as difficult to avoid measuring.

32. Angle Locator

This is a manual tool like an earlier times weight machine with a digital display. Like a protractor, this one is also popular in construction sites and carpentry purposes. Moreover, it is different from an angle gauge except for its look. Firstly, you should step forward with an angled workpiece and place it in the right condition of the ruler-shaped angled corner to determine the workpiece angle.

EspeciallyEspeciallyin cramped spaces angle measurement, it works like a determinant. If you have found an angle inside your closet and are trying to determine how to measure and take for separate designs and usefulness, then take the angle in the middle of angle locator mutual ends to simplify with the needle pointer without maneuverability.

33. Slope Inclinometer

A smart choice for backend engineers in developing jobs, for instance, woodworking and metalworking, even for determining how steep your object’s particular incline is. It eventually first determines the steepness and then throws back the exact info, meaning reading of the measurement as per your expectation.

Somewhat a slope inclinometer resembles a small kitchen Just after a few looks, you can easily verify the differentiation one after another reading test. First bubble or slope inclinometer to zero pointers, then take the joint to the place where you want to measure something. Now see the changes.

34. Framing Square

Another angle measuring tool is needed in your workshop and that is a framing square. Any certain operation it can support to do? Well, including angle measurement, according to its name it has laid out and frame marking offered in its mechanism, as well as the construction. All inclusion patterning in frames, you can consider it in need of stairway work and roofing.

Users can apply it as a substitute for straightedge until it offers a big deal, for instance, determining an object’s surface and its flatness. Though it has a compilation with a speed square, fortunately, the coordination has 2 versions like a small and another is the larger one.

However, we prefer the larger framing square model in terms of maximum collaboration with our carpentry jobs. Therefore, take a wide stock and step forward with the handy cutoff marking over any of its angles.

35. Try Square

Apart from their carpenter square or an official named framing square, try square is a measuring tool to optimize accuracy with the aligned corners of a wooden item, even not a big deal for handling numerous metal pieces too. However, a try square has metal in construction, such as Steel or Cast Iron with a single marked piece of wood.

Try square accuracy refers to 0.002mm per 10mm length. How will you take the reading? Well, if you have noticed once, a right angle in 90-degrees is a burr slot that meets in the center of that 90-degrees angle. Then fit the blade of the straightedge to check its straightness.

36. Plumb Bob

To establish an accurate vertical line, an object connected with a string can take the optimal reading of it. In ancient times, plumb bobs were used to make heavy-weighted vertical-shaped stones, yet in later ages, they turned into the production with cast Iron or Steel. Plumbum is a Latin word that refers to lead and as it casts from lead, the name plumb bob suits a lot.

Being an aid to vertical construction of walls, or building a door jamb, in fact, try some other things to measure properly. However, plumb bobbing is also a name of a mechanism that works on the putting green to search for a way when that putt will break. When the ball squats down behind itself with your putter handing in the blink of your eyes.

37. Moisture Meter

The moisture meter above-mentioned differs as per the environment. For measuring normal moisture ranges of wood, trees, environment, cloudy weather, and more to get the jobs done. Even meteorological departments of each country of the world hold high-end featured moisture meters to detect moisture content percentage in different materials, in fact, for construction sites and making purposes of Steel or Aluminum items.

Ranging between 0 to 100 is often applied to detect moisture content in non-wood materials, and in the relative scale, the lowest range is bone dry and the highest range is saturated. In terms of wood or non-wood materials, the content range differs, for instance, 6-10% for wooden pieces, and below 1% is for concrete and cement items.

38. Compass

A compass is a gadget that shows the main headings utilized for route and geographic direction. It normally comprises a charged needle or different components, for example, a compass card or compass rose, which can turn to adjust itself to attractive north.

There are two main types of compass:

- Magnetic compass and

- Gyro compass.

A compass works by recognizing the natural attractions of the earth. This permits the needle to all the more likely respond to close attractive fields. Since the opposites are drawn towards each other the south pole of the needle is drawn towards the normal attractive north pole of the earth.

39. Wheel Measure

The wheel measure is an instrument used to measure distances, otherwise known as an accessor wheel, click wheel, perambulator, odometer, washer, or troll wheel. It has an element that checks the number of turns and determines the distance using the circumference of the wheel.

There are different types of measuring wheels such as

The small measuring wheel is 4 to 6 inches in diameter. The medium-sized wheel is 6 to 12 inches in diameter. The large measuring wheel is 15+ inches in diameter.

Although the measuring wheel is an approximation instrument. Even then the measurement wheels can be accurate at every 100 feet 3 inches, it is +/-. Deviation from a straight line will similarly affect accuracy.

40. Paint Thickness Gauge

A paint thickness gauge (additionally alluded to as a paint meter) is utilized to gauge dry film thickness. It’s likely the most basic estimation in the coatings business as a result of its effect on the quality, covering interaction, and cost.

Generally, a ruinous test technique is utilized to decide paint thickness. Today, the main role of ultrasonic testing is to measure the total thickness of a regularly drawn frame structure in the range of 3-5 mm.

How the paint thickness gauge works: such as

You keep it tall at a higher level. The instrument, at that point, will measure the distance with the sensor between the bodyboards under the paint. The distance is the thickness of the paint. For instance, if the absolute thickness of the paint is 0.2 cm (0.08 inches), the presentation will show 2000 µm (micrometers).

A Short Overview of Measuring Tools

| Tools | Function |

| Bore gauge | Hole/Bore Measurement |

| Calipers | Breadth, thickness, and depth measurement |

| Angle plate | Marking, Adjustment |

| Center gauge | Used in lathe machine, angle reformation |

| Coordinate-measuring machine | Specifies position on a linear surface |

| Combination square | Marking 90° and 45° adjustment |

| Drawbar force gauge | Force analysis |

| Cylindrical-coordinate measuring machine | Specifies the position in a cylindrical object |

| Gauge block | Measuring standard |

| Feeler gauge | Gap widths |

| Height gauge | Determining the height of an object |

| Machinist square | Adjustment of the proper alignment |

| Dial Indicator | Run-out, deck clearances, thrust, surface linearity |

| Marking gauge | Marking to cut out, woodworking, and metalworking |

| Machinist square | Adjustment of the proper alignment |

| Profilometer | Surface roughness measurement |

| Optical comparator | Inspect and measure the dimensions of small manufactured parts |

| Sine bar | An angle very accurately or face locate any work to a given angle |

| Radius gauge | Measure the radius |

| Square (tool) | The correctness of the angles |

| Snap gauge | Justifies the dimension of separate parts |

| Surface plate | Precision inspection, marking out (layout), and tooling setup |

| Straightedge | Drawing straight lines and checking straightness |

| Wiggler (tool) | Edge-finder, center-finder or laser-centering-device |

| Tape measure | To measure size or distance |

| Thread pitch gauge | Reference tool in determining the pitch |

| Compass | For Land Navigation |

At the Bottom Line

All of the measuring tools you need in your workshop are not possible to present in front of your eyes in brief. For your concern to check out the emergency tools, as well as for shorter and well-informed thorough reading, such different measuring, and detecting tools are available either online or offline shops.

Apart from the described devices in our listing, such common and inevitable toolkits are also available and we have experienced too along with the above-mentioned toolkits. Moreover, our depot concern should give a breeze while purchasing a short checkout for spending your worthy bucks.

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.