Generally, the dial bore gauge allows one to measure devices used for accurate measurement to hole. That means it can measure the internal hole of a cylinder with better speed and accuracy. As we know, it comes with a dial indicator for the reading display in real-time. This tool is used to measure the hole’s diameter. And it is commonly used by engine builders or machinists.

Dial bore gauge is allowed to calculate a boar directly. And a good gauge always provides the desired result. You get accurate measurements most easily and faster. It is the best use of your money.

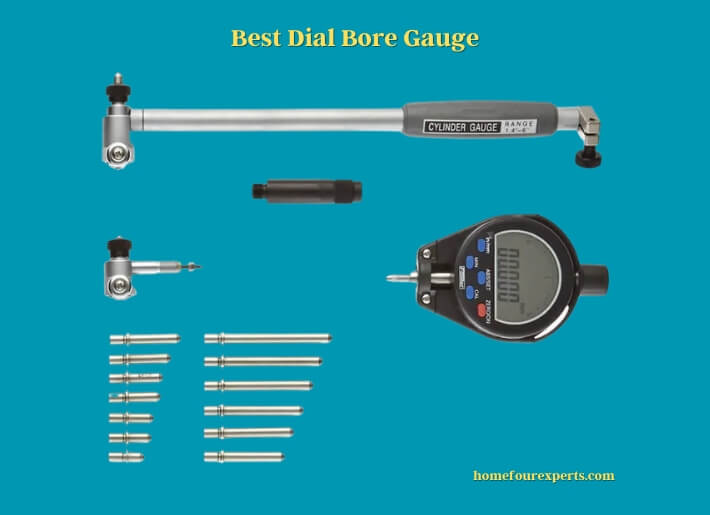

If you want to purchase a new dial bore gauge, then this article is for you. After a lot of reaching, we made a shortlist of the best dial bore gauge kits. There are seven dial bore gauge tools well described.

Choose one as your needs. If you do not have money issues, you can choose the Mitutoyo dial bore gauge tool as the best choice for you. Otherwise, you can choose any one from our list. All come with good features.

How Many Parts Has the Dial Bore Gauge

There you know the basic knowledge about the thing that will help to purchase a gauge. But get an evident concept about a bore gauge you know all the parts of. These are significant parts of a dial bore gauge.

- Dial Indicator: It helps to read the measurement.

- Adoption Screw: You can change your dial indicator with another dial indicator. Just unscrew this adoption escrow part of untightening it. Then you can replace it easily.

- Grip. You can control the bore gauge by the part.

- Gauge head: Last part is the gouge head. This part has few sob parts. They are described below.

- Anvil: This part contacts the bore’s wall. They are divided into two parts: an interchangeable anvil and another moveable anvil.

- Centering contact: This part also contacts the bore’s wall, but it also helps the anvil in the correct position.

Difference Between Dial Indicator and Digital Indicator

Nowadays, all dial bore gauges do not come with a dial indicator. Some come with digital indicators. That means we are divided in two ways.

- Dial indicator and

- Digital indicator.

Both indicators offer mainly the same features. But also some quiet differences let’s know about those facts.

Dial indicators can transfer the result into another device like a pc, smartphone, or laptop. On the trisection, there is no need for any wire. There you can use Bluetooth in this case.

A digital indicator provides more advantages than a dial indicator. There are easy setup procedures of zero reading, no need to calculate by the scales and convert inch to mm.

However, both are good for their place. It is a little expensive. But when time is a matter for you, then you can choose the digital indicator.

How to Choose a Good Dial Bore Gauge?

You have to have strong knowledge about all its body parts. Our article will help you to choose a good dial bore gauge for you. There is a buying guide in our article. Here we describe what things should be essential to buy this tool.

Make sure your bore gauge comes with a 0.0001-inch resolution to get an accurate measurement.

How to Take Accurate Measures With a Bore Gauge?

Machinists use a dial bore gauge to measure the inner diameter of bores. Using this tool can save valuable time. Now we know how to take accurate measures with a bore gauge tool. Read the below-

- Place your gauge with the micrometer locked in the same diameter.

- Now rotate its dial unit with the 0 points.

- Inside your dial, bore gauge into the bore and make sure all avils touch the walls.

- If the tool is squared, then the same pointer shall be started for reserve and head in the opposite direction.

- Record the two-point measurement. Where the bore gauge pointer reverses and removes from the hole.

- Now remove the bore gauge and add the recorded value from the target numbers.

- Example: If your bore gauge was 0 to 2 inches. And the pointer changed direction was 0.007 inches, then 2.007 inches is the final measurement of the hole.

What Is the Ideal Tool for Measuring a Cylinder Bore Inside?

A dial bore gauge tool is usually used for measuring a cylinder bore inside. Because they come with higher portability and are easier to use, they are popular in the market. They are also heaving few moving parts and do not require high knowledge to use it.

How to Use Mitutoyo Internal Measure Cylinder Tool Set

Mitutoyo is the most popular and trusted product in the market for its performance and accuracy. This item provides quick and efficient results. And comfortable use. Here we share a video where you can learn how to use this tool.

What Purpose Is a Bore Gauge Used for?

A bore gauge is one kind of instrument that is used to measure the internal hole. People also know it by several names like- hottest, bore mics, hole tests, cylinder tests or internal micrometers, etc.

How Many Types of Bore Gauges Are Available in the Market?

There are several types of bore gauges available. But here, we talk about the only dial bore gauge in detail. Let’s know all about them-

- Digital bore gauge;

- Telescopic bore gauge;

- Dial bore gauge;

- Mechanical bore gauge.

Top 7 Dial Bore Gauge Measurement Tool

Are you searching for each dial bore gauge model one by one in the market? But you don’t understand which one is best for you. Then you are in the right place. Here we picked the top 7 dial bore gauge for you. It will help you to decide the best one for you.

1. Fowler X-Tender Electronic Dial Bore Gage kit

- Range of measurement: 1.4 to 6 inches;

- Resolution: .00005 inch/.001mm;

- Numeric digital display;

- Dual reading electric indicator inch or metric.

Are you looking for a dial bore gauge that gives you high durability and accuracy? Then the Fowler X tender 54646401 model is the right choice for you. By using this bore gauge, you can easily read the result in two ways.

- The shape of a bar graph and

- Numbers.

Then you can know which span you would like to make in a minute. And also can change the measurement unit to an inch or millimeter. Just by a click, you can set the desired zero point. In this dial bore gauge, you will find five functional buttons. There are-

- The red button is used to turn on/off the digital indicator.

- The In/mm button is used to convert the unit reading.

- The ABS/SET is used to adjust the zero point or at any position as you want.

- The MIN button was used to start the calibration.

- The CAL button is also used during calibration.

If you need any help using this bore gauge, you can read the user manual of this product. You can find the two measuring heads, one is made in the range of 1.4 inches to 2 inches, and another is made in the range of 2 inches to 6 inches. So, you can change the measurement as you need for your working purpose.

To use this digital bore gauge, you need a CR2032 battery. With this product, you can accurately measure taper, the out-of-round, or cylinder bore.

Pros:

- Comes with extension holders to easily adjust.

- The self-centering feature gives more comfort to use.

- You can simply set up the zero point.

- Gives highly accurate measurement.

- Two-point contact systems help to find the geometry problem.

- It is a digital model that means, super faster and easier to use.

Cons:

- You need the battery power source to operate.

2. Accusize Industrial Tools Ee20-1006

- Graduation:0.0001 inch;

- Range of measurement: 2 to 6 inch;

- Accuracy: 0.0004 inch;

- Stem-length: 6 inch;

- Total weight: 2.43 pounds.

Accusize Industrial Tools 2-6 inch dial bore gauge has high accuracy, making it best for lots of industrial applications. It has a 2 to 6-inch measurement capability. This bore gauge kit offers 0.0004-inch accuracy and 0.0001-inch graduation.

It is designed only to measure a cylinder’s ovality and taper. Ee20-1006 is very easy to use. Because of its tight gripping handle. So, don’t have any slip problems.

This product’s carbide-tipped contact points feature ensures the capability of enduring prolonged wear. The kit also comes with a fitted case. You like it. Because this fitted case is so durable and robust, also keep this tool. Moreover, it is very lightweight so that you can use it for a longer time.

Pros:

- It comes with high resolution.

- Has a bezel lock that can easily adjust with zero settings.

- Also included Optional extension rods to measure the deep hole.

- Easy to read the result with its clear display.

Cons:

- It offers lower accuracy of 0.0004 inches.

3. Igaging Deep Engine Hole Cylinder Measurement Gage

- Measurement deep:10 inch;

- Range of measurement: 0.7-6 inch;

- Accuracy: 0.0005 inch;

- Lightweight.

The Igaging dial bore gauge is ideal for measuring up to 10 inches. It offers super-precise measurements. And very easy to use. You can use it to measure the bore size of your cylinder,out-of-round, and the taper. It gives an accuracy of 0.0005 inches. And also measure the range of 1.4 to 6 inches.

Having the facility to interchange its contact point. This dial bore gauge has jeweled bearings. Also comes at a tiny price and is lightweight.

That’s why it is only used with minimal friction. Don’t apply in corrosive environments. Moreover, it is the best use of your money!

Pros:

- It comes with interchangeable contact points.

- Has measure capability up to 10 inches.

- Dial this indicator’s jeweled bearings to read easily.

- Also included high gauge depth with vast capacity.

- You don’t need to remove points during the measuring.

- This item is highly accurate and has a lot of anvils.

Cons:

- It is ideal for only those people who need to measure wide diameters.

4. Anytime Tools 0.7 to 6 inch Dial Bore Gauge

- Capability up to measure: 10 inch;

- Range of measurement: 0.7-6 inch;

- Accuracy: 0.0005 inch;

- Total weight: 3.24 pounds.

Anytime tools digital dial bore gauge comes with a comprehensive range of work that makes it professional. It can measure 0.7 inches up to 6 inches. And can measure up to 10 inches. This bore gauge offers a carbide tip that helps to get more resistance to wear.

Anytime tools dial bore gauge has jewel bearings. That will ensure it is a compact device, accurate and lightweight. This kit included 11 convenient anvils. That means it has a better abrasion resistance than steel.

The model of Anytime tools offers an accuracy of 0.0005-inch. Also, its jeweled bearings give the best protection. Finally, talk about its case. It is made of ABS plastic, which ensures its durability.

Pros:

- Ability to measure 0.0005-inch deep engine holes.

- Jewel bearing included with this dial bore gauge kit.

- Offers highly accurate measurements and also has 11 anvils.

- Carbide tip included on measuring plunger with this item.

- Super precisional deep engine hole cylinder measurement gauge.

- Included an ABS solid and durable case.

Cons:

- Some users said that its case isn’t padded.

5. Extender Internal Measure Cylinder Tool Set

- Gradient spacing: 0.0001 inch;

- Range of measurement: 1.97 to 6.23 inch;

- Inside depthness: 5.9 inch;

- Accuracy: 0.0003 inch;

- Product size: L-02.

Now we talk about another tool that has a broader capacity. Extender manufactures this internal measure cylinder tool. There are two dial bore gauges in one set. This dial bore gauge set comes with a 1.9 to the 6.23-inch range of measurement.

Like others bore gauges, it features carbide-tipped contact points and better abrasion resistance to ensure long-lasting. This model is straightforward to use. This set included the best quality ABS storage case.

Before starting the measuring, ensure that the point of the indicator is 0 point. This dial bore gauge is easier to get the position accurately than any other tools mentioned above. Also included in the user manual that will help you to set up and use.

Pros:

- Perfect use for deep bore.

- Easily adjusted with different diameter sizes.

- The very most straightforward step to set up.

- Don’t need any secondary tool.

- Come with a wide range of capabilities.

Cons:

- A little bit heavier than the other dial bore gauge.

6. HFS 0.005 inch Gauge Dial Bore Gauge

- Gradient spacing: 0.0005 inch;

- Range of measurement: 2 to 6 inches;

- Inside depth ness: 6 inch;

- Measurement deep:10 inches.

Are you looking for a dial bore gauge to narrow cylinders? Then you need the HFS bore gauge to use. It is designed for measurement diameters 0.7 to 1.5 inches. Moreover, if your cylinder was deep, then don’t take tension. Because it also can measure 10-inch depth.

That time you don’t need to disassemble certain parts of your tool.HFS bore gauge comes with 11 anvils. Those are most useful. And those are used for various sizes of holes. It is also included with carbide tips that ensure this tool’s accuracy and durability.

Don’t forget about its case. It is made of ABS plastic which is very educated. This comes nicely padded. That’s why your dial bore gauge keeps protected when it is not to be used.

Pros:

- The capability of the deep cylinder bore gauge measurement depth up to 10 inches.

- Don’t need to remove pistons – critical wear area from the cylinder.

- Included an ABS storage case and jeweled bearings.

- Most durable internal measure cylinder toolset.

Cons:

- Only suitable for small cylinders.

7. Mitutoyo (511-752) Dial Bore Gauge

- Gradient spacing: 0.0001 inch;

- Range of measurement: 1.4 – 2.5 inches;

- Measuring force 4.0N or less;

- Guide force 6.0N or less;

- Range per revolution 0.01″;

- Face Dial, white face, shockproof, jeweled bearing;

- Dial reading 0-5-0.

Mitutoyo 511-752 is the first product on our list. Why is it the number one position on our list? Because of its high resolution, smooth operating capacity, high-degree accuracy, and capability of a wide range of measurements.

Mitutoyo offers the 511-752 series with complete accessories, making it the best dial bore gauge. This product’s resolution of the dial is 0.0001 inches, and its accuracy is + or – 0.0002 inches. That’s why users mostly like to use it. Mitutoyo doesn’t compromise with their product quality.

What Should Things Be Considered Buying a Bore Gauge?

Most people think that all dial bore gauges have the same features or parts. Essentially, they all use the same principles. But they are not the same features or performance.

Without any knowledge about a dial bore gauge tool, you don’t choose the best model for you. Because there are various models available in the market, you need to read this part. Here we describe all the essential things that should be considered when looking for a dial bore gauge.

Range of Measurement

Measurement range is the essential part of a bore gauge tool. According to Wikipedia, “When a dial bore gauge tool is used a ring-gauge then should be accurate within 0.0001 inch”. So, there is a number that can strongly affect the range, like the cross-section.

Overall, if you are working in a broader area, you have to choose that bore gauge with a decent diameter of 0.7 to 0.6 inches. We found an item on our list, “Fowler X-Tender Electronic Dial Bore Gage kit.”

Bore-Depth

The second important thing needed to consider is the working efficiency of a dial bore gauge. By this work efficiency, you can know how deep it can reach during working on a bore. When you are working on a long cylinder, then you need a more extended range bore gauge. Otherwise, you can choose any range of products.

According to our list, you can choose the Anytime Tools 0.7 to 6 inch Dial Bore Gauge because it offers a high range and quickly reaches up to 10 inches depth.

Tools Accuracy

When you look for any type of tool, there must be knowledgeable about the tool’s accuracy. Most likely, you used the gauge to measure the bore or filling jobs. That is why there are accuracy matters present a lot.

So, therefore it is necessary to select a product that comes with enough accuracy. According to our list, the Extender Internal Measure Cylinder Tool Set comes with higher accuracy, which gives your needle response.

Product Durability

Don’t forget to check the product’s durability before purchasing one. We don’t mean that they would be made of lower durability. Now, let’s get to know how to identify the product’s durability. Make sure your gauge has abrasion features. Because this feature ensures that it can handle the damage which will come with the frequent usage

Storage Case

Don’t choose a gauge without a case. Because the case keeps your dial bore gauge all accessories together and your kit should be safe in a case. Some cases come with padding for more safety, and some come without padding.

It must be the case made by which material. ABS is the most durable material which makes the storage cage. When the gauge is not to be used, then the case is helped to stay together and protected.

Gauge Weight

To efficiently carry them might be lightweight. And also easy to use correctly. Most of the products in the market come, lightweight. But sometimes, it depends on how many accessories you need with the gauge. Or if you need a gauge without any accessories, then it will be so lightweight and simply easier to carry.

Final Talk

The dial bore gauge is one of the handy type devices. If you need an exact measurement of bores, then the accurate dials and the measurements will help you successfully do your job. Here we talk about seven different dials bore gauge products. If you need a dual reading electric indicator, then you choose the Fowler XTender dial bore gauge.

If you want a bore gauge for your various industrial applications, then the Accusize Industrial Tool is suitable for you. Or if you need deep bore measurement, then the Anytime Tools 0.7 to 6 inch Dial Bore Gauge and Extender Internal Measure Cylinder Tool Set will be the right choice for you. So, make your choice as your needle requirement.

Read more:

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.