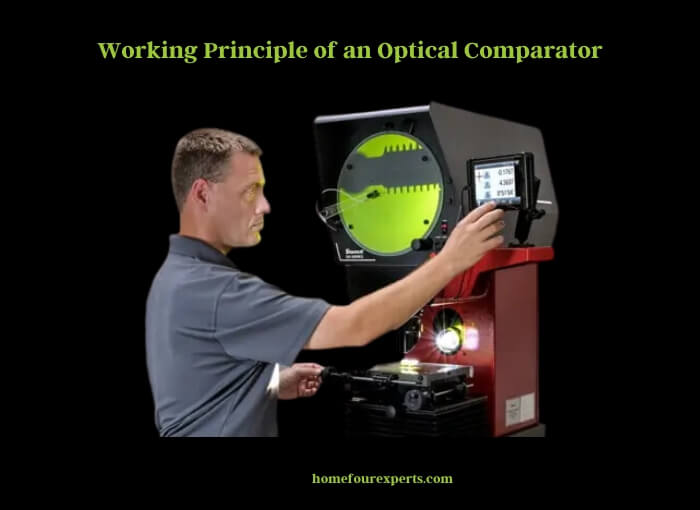

It is a smart idea to use an optical comparator for measuring manufacturing components with ease. But, if you don’t know the working principles of this tool, you will not be able to complete work without all the hassle.

The working principle of an optical comparator is similar to the microscopes along with classroom projectors. It is necessary to fix the target on the stage and light shines on the target. Then the shadow focuses on the target screen.

Read up more?

Concentrate on this article, I show here in detail the measurement principles of an optical comparator as well as some related info on this consequence.

What Is an Optical Comparator?

Optical comparators, one kind of measurement tool, are suitable for use in the manufacturing industry. Also known as profile projectors and shadowgraph. According to Wikipedia “An optical comparator or profile projector is a device that applies the principles of optics to the inspection of manufactured parts”. This awesome tool works for measuring dimensions of the several manufacturing parts by utilizing lenses, illumination, or mirrors.

Highly maintain the optics principles. Alternatively, there is no major difference between the optical comparator and optical microscopes. An optical comparator allows checking scratches and indentations dimensional accuracy. So, no doubt, these tools are excellent for non-contact measures.

Working Principle of Optical Comparators

The working principle of optical comparators is dependent on the type of comparator as well as the reflection & refraction of the light’s laws. They collect large magnification to give users a high degree of measuring accuracy. This magnification procedure is conditional on the defects in a beam of light and tilting of a mirror.

Though there are no authentic optical comparators, all-optical comparators are based on the instruments. Optical comparators have two major configurations as horizontal and vertical. Here are the working principles.

Horizontal Comparator

The horizontal comparator’s light travels horizontally. In this case, viewers look at shadows seized from the side of the part. Horizontal models are the best choice for the fixed location.

Vertical Comparators

The vertical comparator has light travels vertically. In this case, viewers look at the down part. This model is good for smooth components that lie on the work stage for providing a precise measurement. Also, it works well with flexible and smooth elements.

Anyway, the working principle of the optical comparators has changed little. Uses optics technology that means changing the quality, not function. Generally, comparators are similar to the overhead projector and are used in the classroom. Utilizing the sequence of mirrors & lenses, a target is set on the stage as well as light is enlightened through the target from underneath.

So, light shines on the stage and makes a shadow image onto the screen. The shadow is highlighted by mirrors and lenses. There are different sizes of optical comparators. These are dependent on the screen size, optics, and magnification of the projected image. The larger screen size of the optical comparators is from 12 to 36 inches available in the market.

Alternatively, the optical comparator varies according to the measuring process. Three various measuring processes are following the comparators.

Shadow Measurement

One of the simplest but accurate measurement processes is shadow or silhouette to accumulate images onto the screen to measure.

Point Comparison

This is another easy measurement process. In this case, comparing the image’s silhouette is to a defined strategy point on the screen. When the silhouette part is centered on the screen, users can move the stage by hitting different parts of the screen.

Software Analysis

The software analysis process is digital that is used to measure & verify the image creation. But shadow measurement and point comparison methods are traditional and are used by the most common optical comparators. By the way, the software analysis method works electrically.

Different Parts of the Optical Comparator

The main parts of an optical comparator are pivoted lever, objective lens, scale, plunger, mirror, table, and base. All of the parts are essential to measuring accurately. The most crucial part is the objective lens. It is used to convert light rays. Alternatively, the pivoted lever is pivoted near plunger movement.

Where plunger is fitting in one end and mirror is fitting another end of the part. Another important part of the optical comparator is the screen and scale that helps to display readings. To reflect the incoming light rays, a mirror is used. The plunger, table, and base are also useful parts of an optical comparator.

Advantages of Optical Comparator

An optical comparator, a versatile measurement tool, comes with numerous advantages. It works to measure length and width along with indicating possible shortcomings more than other devices. This measures two-dimensional space that is different from micrometers. The basic advantage is that it is easy to use from novice meteorologists to experts. Provides a great deal of input within a quick moment.

Other advantages are below:

- Optical comparators offer to measure more delicate parts without any risk. They are light and easy during the measuring time just because of fewer parts.

- Most importantly, these devices are affordable so that you can save your money and reduce inquiry time.

- The ergonomic design makes it more attractive.

- Contains few moving parts and provides high accuracy.

- There is no parallel error.

- Its high magnification supports measuring correctly.

Disadvantages of Optical Comparator

Though optical comparators are very useful devices, they have some disadvantages. Some users think it is quite expensive considering its quality. Other disadvantages are below:

- Only good for using in any dark room.

- Need a separate power or electrical source

- Users can not use the optical comparator continuously because of the scale capable of viewing through the eyepiece.

Frequently Asked Questions

What Are the Types of Comparators?

There are different types of comparators such as optical, electronic, sigma, electrical, mechanical, digital, pneumatic, and more. Several comparators are suitable for use in multiple applications. These play an important role in conceiving electronic projects. Without feedback, they are designed to open circle composition. The main types of comparators are below:

- Mechanical Comparator

- Mechanical-Optical Comparator

- Reed Type Comparator

- Electrical-Electronic Comparator

- Pneumatic Comparator

What Is the Accuracy of an Optical Comparator?

An optical comparator provides easy as well as an accurate measurement. Anyone can measure the angles projected on the screen with accuracy within a few minutes of one degree. The most widely used magnification is 10X.

How Precise Is an Optical Comparator?

An optical comparator is similar to a classroom projector. Uses magnification input video or image onto the background screen. This device supports making images on the screen with accuracy. Also, offers precise and accurate measurement.

What Is a Digital Optical Comparator?

The main purpose of an optical comparator is to assess products by using optics. The digital optical comparator works electrically. This can save time and you don’t need to work manually.

Verdict

Ultimately, it is straightforward to use an optical comparator just knowing the working principles and another essential thing. Anyone who has a lot of ideas or not can handle it with ease. Regardless, I have already validated everything about optical comparators, their advantages & shortcomings, and more.

Featured image credit: starrett.com

Read more:

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.