There were only two types of saws available in the past when saws were primarily used for woodworking: crosscut teeth saws and rip teeth saws.

Despite having diverse names and being designed for a range of tasks, most power saws may be classified into one of two categories.

A crosscut saw blade has more teeth (80) for a smoother cut with less tare out; simply maintain the blade half an inch or more above the top of the wood you’re cutting. There are 28 teeth on a rip blade. It will shave the wood as if it were butter. When ripping with a crosscut blade, the wood will be cut very slowly and may even be burned.

How Can You Tell the Difference Between a Rip Saw and a Crosscut Saw?

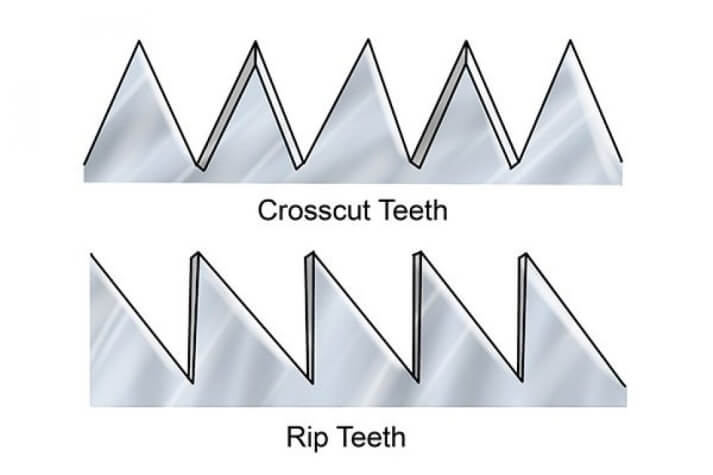

One of the most significant distinctions between crosscut and rip saws is the blade design. The blade teeth on both saws will be twisted away from the blade. The teeth on crosscut saws are inclined on the inner edge, while they are not on rip saws.

The teeth on a crosscut saw are intended to cut across the grain of the wood. Crosscut teeth saws are suitable for this activity because they are often more challenging.

Rip teeth don’t have an angled edge, so they function more like little chisels, scraping away at the wood rather than slicing through it. Rip teeth are made to cut with or against the grain. Rip teeth saws are the preferable alternative because this is often regarded as a simpler process.

What Is a Rip Saw Good for?

A rip saw is a wood saw that is specifically intended to make a rip cut, which is a cut that runs parallel to the wood grain.

Combine the saw with a miter box for unique degree cutting and angles.

A rip blade is the greatest saw blade for ripping hardwood. Because this blade is designed to cut through wood fibers, it will readily cut through hardwood and leave a clean edge. Rip blades typically feature 10 to 40 flat-topped (FT) teeth, which is a tiny number, but it allows the blade to go fast through the grain.

The rip saw is best used in wood projects that require cross cuts with rips and when this is the demand no other saw can be preferred to the excellent rip saw which is especially designed for the purpose of framing out facades of wood and its designing.

The capability of the rip saw to give out ripped cutting is one such advantage of the saw that makes it a demanding one among the users due to its easy maneuver of handling the saw.

Who Can Use the Rip Saw?

Regardless of the user’s ability to use a saw, the design, size, and functionality of the saw ensures that it is never a letdown.

Amateur or the Novice Wood Dealers

The saw is one that may be quite useful for those who are new to the wood cutting area and have yet to learn a great deal about material cutting maneuvers. The saw is a hand-held device that requires physical assistance to cut out materials. As a result, this can assist novice users in learning cutting and other sawing methods from a young age.

Regular Wood Tradesmen

The saw may be a fantastic buddy to tradespeople who are always engaged in wood cutting deals on a regular basis since it is light to carry with them wherever they go and also because it is a manual module that is always available for any sort of task at any time.

What Is a Rip When Using a Saw?

Cutting a board lengthwise or parallel to the grain is referred to as ripping a board. (Cross cutting refers to cutting perpendicular to the grain.)

What Is a Good Rip Capacity?

A rip capacity of 30 inches is preferred by many experienced contractors since it handles the bulk of the cuts. The majority of contracto Is it possible to tear cut using a crosscut blade?

Short grain is cut using the Crosscut blade, whereas long grain is cut with the Ripping blade. With the Combination blade, you can cut crosscut and rip with the same blade.

This rip capability is achieved using r saws.

What Is the Meaning Crosscut Saw?

The term “crosscut” refers to the cutting, going, or moving across or through something. Any saw designed to cut wood perpendicular to (across) the wood grain is known as a crosscut saw (thwart saw).

Crosscut saws can be tiny or big, with small teeth close together for fine work such as woodworking or huge teeth for abrasive work such as log bucking, and they can be used by hand or by power. (source)

Each tooth’s cutting edge is inclined in an alternating pattern. In contrast to a rip saw, which tears along the grain and acts like a little chisel, this design allows each tooth to function like a knife edge and slice through the wood.

Rakers are unique teeth on some crosscut saws that clear away the cut strips of wood from the kerf. Teeth on crosscut saws are typically smaller than those on rip saws.

Some saws, such as those used by the ancient Egyptians and Japanese saws, are intended to cut exclusively on the pull stroke. On the other hand, Western saws are built to cut on the push stroke.

What Is the Purpose of a Crosscut Saw?

Any saw designed to cut wood perpendicular to (across) the wood grain is known as a crosscut saw (thwart saw). Crosscut saws can be tiny or big, with small teeth close together for fine work such as woodworking or huge teeth for abrasive work such as log bucking, and they can be used by hand or by power.

What Is a Crosscut Saw Used to Cut?

Crosscut saws are used to cut wood across the grain, whereas ripsaws are used to cut wood with the grain. The manner the teeth are ground is the major variation between the saws.

How Many Teeth Does a Crosscut Saw Have?

Crosscut saw tooth designs are common. Crosscut saw teeth are smaller and more tightly spaced (8 to 12 tpi), with leading edges that tilt toward the handle for clean cuts across the grain on 10-inch blades with 60 teeth and 12-inch blades with 80 teeth.

Does the Ripsaw Have More Teeth Per Inch Than a Crosscut Saw?

Because a ripsaw is designed to cut with the grain rather than against it, it encounters significantly less resistance than a crosscut saw. As a result, ripsaws have bigger teeth and fewer teeth than crosscut saws. There are 5 or 6 points per inch on a conventional ripsaw.

How Do You Use a Hand Rip Saw?

One of those essential skills that any homeowner, DIYer, or woodworker should aspire to master is how to use a hand saw. While powered saws have their place, if you’re working somewhere without access to electricity or your batteries are running low, a good hand saw is your best bet for the job.

How to use a hand saw – guide

Mark the Cutline

Remember the old carpentry adage: measure twice, cut once. Measure twice (of course) and draw a line to indicate where you want the cut to be made. The line will serve as a guide to ensure that your cut is straight.

The Initial Cut Should Be Made

To guarantee that you cut along the cutline, as a guide, use your thumb or the knuckle of your thumb on the hand that is holding the wood.

The saw should be angled appropriately. To achieve the greatest cut, tilt your saw appropriately after you get your kerf flowing. The correct angle between the saw and the wood for crosscut saws is 45 degrees. It’s 60 degrees with ripsaws.

Maintain a Tight Grip on Your Body With Your Elbows

When sawing, keep your elbows close to your torso to prevent the natural inclination for the blade from sloping away from vertical. This will also keep the blade from twisting and tilting, resulting in a beautiful, crisp cut.

How Should I Hold the Saw?

Simply grasp the handle with your fingertip extending along the handle’s side. This allows you to “point” the saw down the line, resulting in more precise cuts. Maintain a strong but not overly tight hold on the handle.

The Action of the Stroke

After you’ve started the groove:

- Make a few quick forward strokes to deepen the cut and free your left hand from the blade.

- Use a smooth, free-running action to push the saw.

- Use extended strokes to ensure that each tooth contributes equally to the effort.

- Short strokes cause the saw to be dull more quickly since just a few of the teeth are used.

Don’t Give in to the Urge to Pound on the Saw

It won’t do anything but exhaust you. Allow the saw to handle the heavy lifting. If the saw isn’t cutting properly, there might be a problem with the saw itself.

Use a 24 as a Reference for Straight Cuts

Using the pencil line as a cutting guide is ineffective for many guys. Place a 24 (or 22) along your pencil line and clamp it to the board you’re cutting to guarantee you obtain a true and square cut. The board will now serve as a guide to keep the saw on the straight and narrow.

Veering Correction

Even the greatest carpenters deviate from the cut line from time to time. If this occurs, resist the natural urge to twist and bend the saw blade in order to bring it back on course. This will simply result in a sloppy, uneven cut. Instead, pause your sawing and return your blade to the place where you strayed. Return to the line and resume sawing.

Binding With a Nail Is Not a Good Idea

Binding is a difficulty that you may have while using a rip saw to cut along the grain. Binding happens when the kerf closes in on the saw. To avoid this, just hammer a nail into your kerf. It will remain open as a result of this. As you see, move the nail towards you.

How Does a Straight Line Rip Saw Work?

A fence is included on a straight line rip saw; however it is mostly used to direct the board into the conveyor. For ripping random-width material, several industries employ straight line rip saws. Straight lines are extremely adaptable, allowing the operator to tear almost any combination from a cut list.

Final Words

Short grain is cut using the Crosscut blade, whereas long grain is cut with the Ripping blade. You can cut crosscut and rip with the same blade as the Combination blade.

It is never good to use a crosscut power saw to shred a board since it is quite risky. The number of bigger teeth on circular saw blades meant for rip cutting is less than on blades suited for crosscutting.

If you’re a perfectionist who demands the greatest results, start with task-specific saws such as ripping and crosscut saw. If you’re not sure what sort of saw you’ll need, a nice general-purpose saw should suffice for now.

You might also like:

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.