Have you been thinking that fixing a broken axe handle is a woodworker’s job? Well, it is. But following a simple procedure and some regular tools, you can do it too! Yes, you are reading it right.

Removing the old axe handle and inserting a new one is no big deal. The most tricky part here is to buy a good quality handle and that’s all. Don’t worry, we have covered up that as well. You will also get to know how to choose a good handle for replacement and many other frequently asked questions about axe handles.

Following the same procedure, you can remove and replace hammer, mallet, and hatchet handles as well. This is the most effective way to give a new life to the years-old, family treasures. Remember, longevity is the evidence of effectiveness for these solid handmade tools. Buying a new axe will take years to prove its reliability.

Does Axe Handle Worth to Replace?

If the axe had lasted a few generations, then the handle is worth replacing compared to buying a new axe. Buying a cheap axe is easier than replacing a handle from a century-old axe. But it is more likely than the axe that is cheap and also made cheaply. Axes that are made of recycled or scratch material are found cheap. Those heads break faster than the wooden handle.

On the other hand, Swedish, American, or German steel-made axe heads last for decades, even centuries. Only these axes are worth replacing their handles. These are the finest and most expensive axes in the market.

Replacing the broken or worn-out handle is cheaper than buying a quality axe in this case. People who know the true worth of a solid American axe prefer buying a second-hand axe at a low price and replace the handle and do proper sharpening to reuse it.

Procedures to Replace Axe Handle Like a Pro

Replacing an axe requires many tools, but all are available at our home or workshop. But it does need a little time and caution. If you can guarantee patience and consistency, then here are the steps that you need to follow for a successful axe handle replacement project.

Equipment Required for Axe Handle Replacement

New handle, vice, saw, wood wages, metal wages, wood glue, sandpaper, pencil, boiled linseed oil, hammer, and punch.

Step-1: Remove Old Handle

If the old handle is still attached to the axe head, it has to be removed. There is a particular way to remove the axe handle without damaging the head or blade. Set the axe on the table and use a saw to cut out the axe handle from beneath the head. Then use a punch and hammer on the cut-out side of the axe head to push out the remaining handle from the axe handle.

Now use the same punch and hammer to put a mark on the top side of the axe head. The size and shape of the top and bottom of the axe head look similar but are not the same. The marking will help to find out the top part while attaching a new handle.

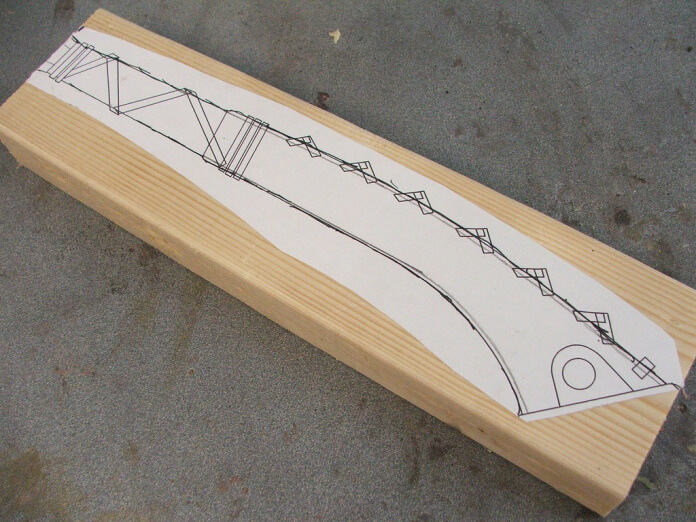

Step2: Prepare New Handle for Adjustment

Ready-made spare axe handles are not made the exact size of the axe head. The handle has to be customized according to the axe head size. To do that, you should first try to pass the axe head to the new handle. The axe head will not be able to pass more than an inch. Mark that spot with a pencil.

Now remove the head and use sandpaper to remove material from the axe handle. We wish to make a snug fit of the head on the handle. So, too much material can not be removed from the handle. Try placing the axe head closer to the widest part of the handle in between sanding. When you are able to do it, stop the sanding process.

Step-3: Set the Blade on New Handle

Now place the axe head on the handle, the market surface facing the top. Grip the axe head and tap the handle against the floor. The axe handle will slide down a bit and stitch above the wide part of the handle. Now use a saw to cut off the extra bit of handle wood sticking out of the top part of the axe head.

Step-4: Insert Wooden and Metal Wages

Take the wooden wedge that comes with the spare handle. Apply wood glue halfway on the thinner edge. Then try sliding the wedge in between the slit of the wood that’s visible from the top of the axe head. Use a hammer to push the wedge all the way down.

Now it’s time to insert metal wedges the same way. Take the metal wages from the old handle or use new. If the axe head is big, it will require two wedges. For a small head, inserting a single wedge at an angle is okay. Use a hammer to push the wedge all the way down to the axe head.

Step-5: Sand, Polish, and Oil the Handle

Your axe is all set to use now. It only needs some finishing touch. Use 180 sandpaper to brush off any scratch or nicks that might develop from all the hammering, tapping, and clamping of the handle.

Then wear a pair of rubber gloves and rub boiled linseed oil on the entire handle. Use the oil to the wedged part as well. Reapply the oil three times followed by a 20 minutes break. The oil will help the handle to be waterproof, weatherproof, and long-wearing.

FAQs

When Does the Axe Handle Need to Be Replaced?

When the axe head is coming off the handle from the top, or the handle is broken, or split, the axe handle definitely needs to be replaced. People usually replace the handle when it is worn, but only a few can tell that the head is coming loose.

In fact, a loose axe head is way too dangerous than using the axe with a worn handle. Because the loose axe head can fly off in the mid-strike and injure anyone. So these are the signs that your axe handle needs replacement.

How to Buy a Spare Axe Handle for Replacement?

The following things should be considered while buying an axe handle.

- Always buy an unpolished handle. Because oil is used to cover up the imperfection of the wood. Buy a bare handle and you can apply oil later.

- Choose a hardwood white handle. Make sure that the handle does not have any knots on it.

What Type of Wood Is Used for Axe Handles?

Axe handles are made of hardwood. American hickory, maple, or ash wood handles are the best choices. These woods can take shock compared to other hardwood materials.

Should You Oil an Axe Handle?

Yes, you must. An oiled axe handle lasts longer than a bare handle. Linseed oil is applied to an axe handle. I prefer using boiled linseed oil. It is expensive but worth the price as it gives better protection to the axe handle.

Bottom Line

So you see, neither removing the old handle nor inserting a new one is as tough as it sounds. As long as you follow the steps I have described here, you are good enough to do it alone.

After replacement, always take proper care and maintenance of your axe. Keep it sharp, clean, and store it well. Maintenance is the only key to the longevity of a good quality axe and its handle.

Read more:

About This Writer

Hi, I am Eric Devin and I am a professional interior architect. Since childhood, I've always enjoyed DIY projects! And, I have loved to solve simple household problems using essential tools and equipment. I have also acquired a lot of information about basic household tools settings by working with contractors.