It is clear that if you use any miter saw continuously like frequently, it can be changed or damaged. Of course, ridgid miter saws are one of the most popular and usable saws nowadays. But, when you are cutting several materials as necessary, or continuing to transfer it, or more factors, your saw is not able to square cuts.

Fear not! You can square it again. Just align as well as adjust each of the equipment. Once reading the below article, you find everything needed to do this job.

We discuss here some simple steps to square your ridgid miter saw without any hassle & basic information about ridgid miter saws.

Are Ridgid Miter Saws Good?

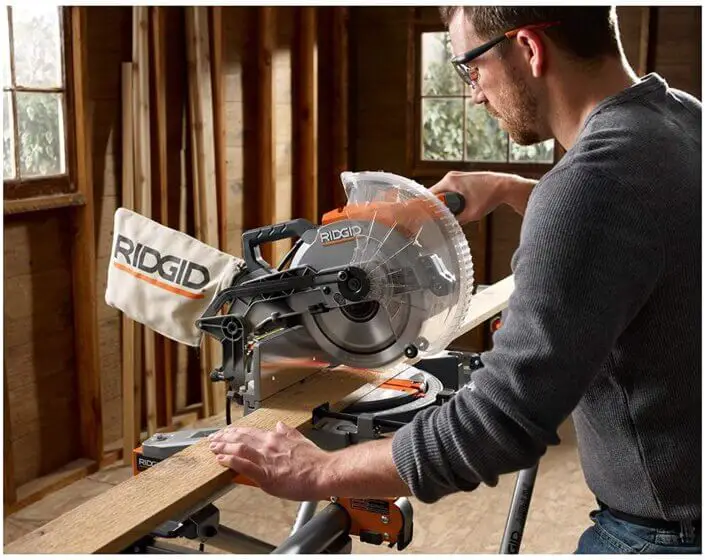

Ridgid miter saws are good or not; it depends on the user’s demand and their satisfaction. But, the company provides the guarantee that this dual bevel sliding miter saw is capable of handling any type of cut. Even suitable for 70-degrees to the right or left cut.

It comes with a 15-amp motor powerful enough to cut through several tougher materials. Plus, ridgid miter saws are lightweight, durable, and a good option for left-handed people. Another excellent thing is its integrated dust collection port. Also, it is easy to move the saw head with the crown molding stops.

On the negative side, this type of saw does not work well for square cuts if you forget to adjust equipment. But, ridgid is overall great for cutting edge smoothness.

Method of How to Square a Ridgid Miter Saw

Ridgid miter saws are extremely good for producing accurate cuts as well as offering easy-to-use control if you adjust the miter gauges. These types of saws are highly used for accurate & square cuts and cross-cutting. But, sometimes the Ridgid saw doesn’t work as accurately as you expect. This is because users have to take some steps to square it. Now that we are going to the main point of how to square a ridgid miter saw.

Step 1:Check Blade

The first important thing is to check the blade. If the blade is located straight, it is ok. But, miter saw blades are flying around at high speeds. So, it can be damaged or warped quickly. Before going to adjust others, ensure the blade’s position and quality.

Step 2: Table Alignment

It is a smart choice for the miter saw users who are interested in setting up a working saw table. It is quite tough to align the table. Sometimes users don’t understand how to adjust it. Ensure that the table is flat and fix the edge of the table straight. Then check it.

Step 3: Square the Fence

Now is the time to square the fence. The fence is supported for cutting the long materials. It stays at the back edge of the table. Without fence alignment, you can’t square your ridgid miter saw. So, find out the spots where fences are not squared.

Unlock the screws for adjusting the fence. Hold it until square. When it is square properly, fasten it as soon as possible back in place.

Step 4: Adjust the Miter Angle

In this step, you have to square the angle of the ridgid miter saw. Two important things that you have to do. First, establish your blade’s bevel angle to 0 degrees and then set the miter angle to 0 degrees. For this reason, your miter angle will be quite adjusted and square with the fence as well.

Then, adjust the fence and blade to square them. One edge of the fence is square against the other edge. Square the blade’s side edge then blade guard.

Find the blade and fence gaps. If any chasm between them, unlock the miter and fasten. Now that the fence and blade are square so that your miter angle is also square properly.

Step 5: Adjust the Bevel Angle

Now, it is important to consider the bevel angle. You should keep the bevel 0-degrees angle and set the table square with each other. Put one edge of the upward and the other edge laying on the table. Ensure that the blade guard is raised. If there is no gap, the blade becomes aligned. Remember that you should place a 2×4 on the edge flat. Now, this step is covered.

Step 6: Accuracy

Ultimately, 0-degrees miter angle, 0-degrees bevel cut, and flat edge against the table and fence make the ridgid miter saw square. After adjusting all of these, check the accuracy of the saw. This is the last step to check your saw’s exactness. You go to turn on and make a cross cut then test the cut’s accuracy using a square level or others. If you get a square cut, your miter saw is okay. But, not getting an accurate cut, you will move through the service center.

Why Is My Miter Saw Not Cutting Square?

Woodworkers who love to get an accurate cut like error-free cuts need to know about the proper use of a miter saw. For cutting squares, you should know the causes of inaccurate cuts. The main reason is the incapacity to clasp the material down. Due to using a damaged blade, the miter saw can not cut square. Other reasons are miter gauge malfunction, unstable fence, or broken bevel gauge.

So, before starting to work, you should check the blade’s sharpness and gauge position. Also, you need to ensure that the fence is in the right stance.

The Bottom Line

At the end of the day, it is not tough to square the ridgid miter saw if there is no major reason that you can’t recover. We already provided six steps of how to square your ridgid miter saw. These steps are simple but effective.

Hopefully, you understood the alignment of the fence, blade, miter angle, bevel angle, and more simple problems. Don’t be late! Just enjoy your task and successfully run the next woodworking project.

Read more:

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.