According to Wikipedia, a radius gauge, also known as a filet gauge, is a tool used to measure an object’s radius. Radius gauges necessitate the use of bright light behind the object being measured. The gauge is held up to the edge to be checked, and any light leakage between the blade and edge indicates a mismatch that must be corrected.

Radius gauges are used in pattern making, precision machining, layout creation, and part inspection to measure existing radii. They are found on a wide variety of objects such as hinges, buckets, taps, tools, and dies.

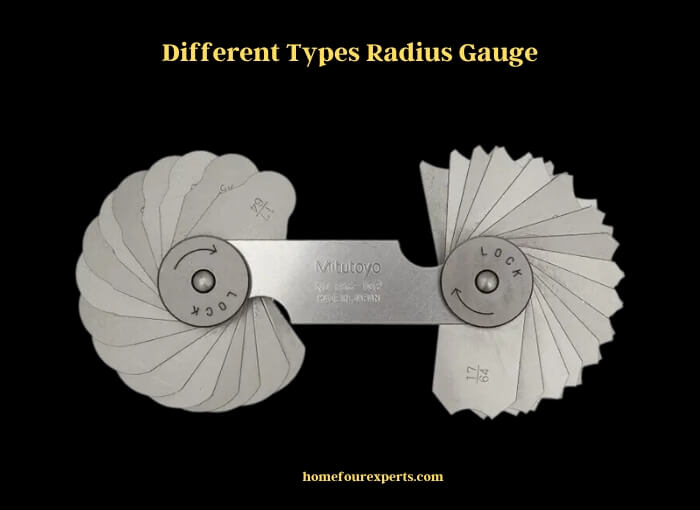

Types of Radius Gauge

You can pick radius gauge according to your choice. The user checks them one by one blade to understand which one is fixed and works perfectly. There are seven types of radius gauges. They are:

Gauge With Single Function Blades at Either End

At one end, there is a blade for measuring concave surfaces. At the other end, there is a blade for measuring convex surfaces; both blades cover the same measurement range.

Gauge With Multifunction Blades at Either End

Its internal and external design allows it to measure concave and convex surface areas. There is a concave and convex measurement on each blade.

Gauge With Five Measuring Surfaces

An instrument with five measurement areas There are five cut-out projections on this radius gauge that can be used to measure (2) concave surfaces and (3) convex surfaces. On workpieces, it is also used to mark precise radii with a sharp point.

Ring Bound Multi-function Blade

It is similar to a radius gauge, but it has multi-function blades at either end. As opposed to being mounted on a handheld tool, they are ring bound instead.

Acrylic Gauge

Radius gauges made of acrylic can measure concave and convex radii, as well. For example, spindles, moldings, and corners are commonly turned with them.

Guitar Neck Radius Gauge

The radius of the guitar neck The radius of a guitar fretboard is measured with a guitar neck radius gauge so that the instrument can be made to produce the desired sound.

Digital Gauge

Gauge on a computer In heavy industrial processes like sheet metal and pipe bending, where large radii must be accurately measured to meet building specifications, a digital radius gauge is used.

What Is Radius Gauge When Is It Used

In this section, we present the uses of radius gauges. Hope this will help the new user.

- Radius gauges are used to measure existing radii as part of pattern making, precision machining, layout creation, and part inspection.

- They are found on a wide variety of objects, including hinges, buckets, tools, taps, and dies.

- When it comes to woodworking, radius gauges are used primarily for layout and pattern-making purposes.

- It’s possible to use an acrylic radius gauge on wood that has been turned on a lathe or after it has been rounded on the edges.

- To ensure that parts fit together correctly, a radius gauge is often used.

- When using a radius gauge, workpieces can be marked with specific radius measurements before being cut out or machined to the desired curve.

- Radius gauges can be used to ensure that diecasts (metal molds) have the proper radius measurement.

What is the Difference Between a Radius Gauge and a Vernier Caliper

A radius gauge, also known as a radius template or fillet gauge, is a tool used to measure the radius of a rounded or curved surface. It consists of a set of thin metal blades of various radii, which can be bent to match the shape of the surface being measured.

A Vernier caliper, on the other hand, is a precision measuring tool used to measure the distance between two opposite sides of an object. It consists of a main scale, which is divided into millimeters or inches, and a vernier scale, which is used to measure smaller increments of measurement. Vernier caliper can be used to measure internal and external dimensions, depth, and step measurements.

In summary, a radius gauge is used to measure the radius of a curved surface while a Vernier caliper is used to measure the linear distances or thickness of an object.

How to Step by Step Use Radius Gauge

1. Choose a Radius Gauge Set to Work With

Alternatively, you can choose a set of single-function blades or a set of multi-function blades. A concave radius can be measured with both gauges, as well as a convex radius.

2. Decide on the Radius Type

A concave or convex radius can be measured. To obtain external measurements, a concave blade is required for a convex surface. Convex blades are needed to cut a convex item (the reverse is true for internal radius measurements).

3. Choosing the Right Blade

Separate a single blade from the casing and expand it. Choosing a blade with a curvature that approximates the size of the radius you need to measure is important.

4. Turn on A Light Source

Make sure that the object being measured is illuminated from the back with a bright source of light. As a result, there is a clear line between the gauge and the surface to be measured.

5. Illuminate a Light Source

The thing to be measured should be held between your eye and a light source to be measured. Due to the visual testing method, this is an observational measurement.

6. Check the Blade Radius

The gauge should be visible through the object you are measuring. Light leaking means the object’s radius does not match the blade’s radius.

7. Align the Blade With the Surface of the Object

Using trial and error, try to fit the blade of the radius gauge to the object’s surface. A blade’s radius can be determined by comparing the gauge’s surface to a certain object’s surface.

8. Adjust the Surface, if Necessary

Uneven curvature of an object’s surface may make it impossible to align any blades. In this instance, the object’s radius may have to be adjusted. To do this, re-cutting, grinding, sanding or polishing the surface are all viable options.

9. Measure the Object’s Diameter

Try again to align the blades with the surface after adjusting. It is possible to read the inscribed me when surfaces come together without gaps.

What is the Best Way to Clean a Radius Gauge

The best way to clean a radius gauge is to use a soft brush, such as a toothbrush, and a mild detergent to gently scrub away any dirt or grime. Rinse the gauge thoroughly with water and dry it with a soft cloth. Avoid using abrasive materials or chemicals, as they can damage the gauge. If there is any rust or corrosion present, use a rust remover specifically designed for use on precision instruments, then rinse and dry thoroughly.

Conclusions

This article presents some basic necessary factors about the radius gauge. It’s an essential tool for the workplace and home. Day to day it becomes very popular for easy use. Radius gauge uses and use steps are also described here. Hope this article helps you a lot.

If you want to know further information let us know. You can connect with us through our media.

Featured image credit: Amazon.com

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.