Metalworking is an essential process in many industries, from manufacturing to construction. Whether you’re a professional metalworker or a DIY enthusiast, having the right tools is crucial for getting the job done effectively and efficiently. In this blog post, we’ll take a closer look at metalworking tools, including what they are, their different types, how to choose the right one, and how to maintain them.

Metalworking tools are tools used for cutting, shaping, and forming metal. They come in a variety of forms, including hand tools and power tools, and are used for a range of applications, from small repairs to large-scale projects. The importance of metalworking tools cannot be overstated; they play a critical role in a variety of industries, including construction, engineering, and manufacturing.

Types of Metalworking Tools

Metalworking tools can be divided into two main categories: hand tools and power tools. Hand tools are manual tools that are operated by hand, while power tools are operated using electricity or other power sources.

Hand Tools

- Hammers: Hammers are a staple in any metalworker’s toolkit. They come in a variety of styles, including claw hammers, ball-peen hammers, and sledgehammers. Hammers are used for shaping and bending metal, as well as for driving nails and other fasteners.

- Wrenches: Wrenches are used for tightening and loosening nuts and bolts. They come in a variety of sizes and styles, including open-ended wrenches, box wrenches, and socket wrenches.

- Screwdrivers: Screwdrivers are used for tightening and loosening screws. They come in a variety of sizes and styles, including Phillips-head, flat-head, and Torx.

- Pliers: Pliers are used for holding, cutting, and bending wire and other small metal pieces. They come in a variety of styles, including needle-nose pliers, diagonal pliers, and wire-stripping pliers.

- Saws: Saws are used for cutting metal. They come in a variety of styles, including hacksaws, reciprocating saws, and jigsaws.

- Chisels: Chisels are used for cutting and shaping metal. They come in a variety of styles, including cold chisels, punch chisels, and center punches.

- Files: Files are used for smoothing and shaping metal. They come in a variety of shapes and sizes, including flat files, round files, and half-round files.

Power Tools

- Drills: Drills are used for making holes in metal. They come in a variety of sizes and styles, including corded and cordless drills, as well as drill presses.

- Grinders: Grinders are used for shaping and finishing metal. They come in a variety of styles, including angle grinders, bench grinders, and die grinders.

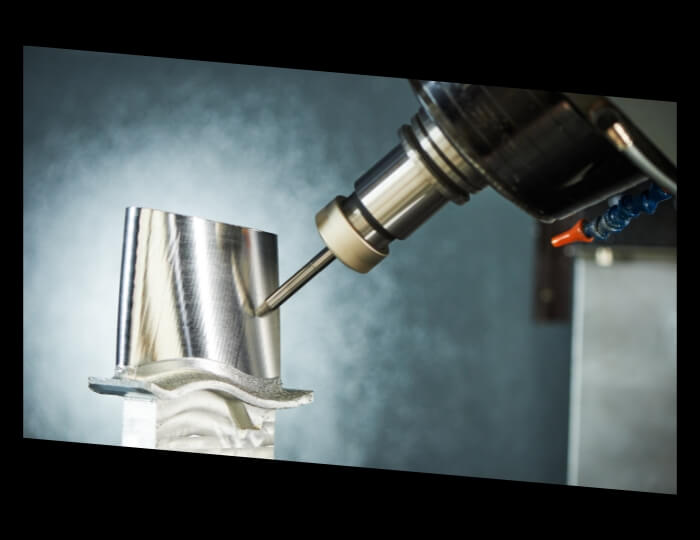

- Lathes: Lathes are used for shaping metal into cylindrical shapes. They are used for a variety of applications, including turning, drilling, and milling.

- Milling Machines: Milling machines are used for cutting and shaping metal. They come in a variety of sizes and styles, including vertical milling machines and horizontal milling machines.

- Bending Machines: Bending machines are used for bending metal into specific shapes. They come in a variety of styles, including press brakes and pan brakes.

- Welding Equipment: Welding equipment is used for joining metal pieces together. There are various types of welding equipment, including MIG welders, TIG welders, and stick welders.

- Cutting Machines: Cutting machines are used for cutting metal into specific shapes. They come in a variety of styles, including plasma cutters, waterjet cutters, and laser cutters.

These are just a few examples of the many types of metalworking tools available. The right tool for the job will depend on the specifics of the project, the metal being worked on, and the desired outcome.

Choosing the Right Metalworking Tool

The right metalworking tool can make all the difference in the quality and efficiency of your work. However, with so many different tools available, it can be challenging to know which one is best for your needs. Here are some key factors to consider when choosing the right metalworking tool:

- The task at hand: The first thing to consider is the task at hand. What type of work will you be doing, and what type of tool is best suited for that task? For example, if you need to make precise cuts, a hacksaw or metal cutting saw might be your best option, while if you need to bend metal, a metal bending tool would be more appropriate.

- Material: The type of material you will be working with is another important factor to consider. Different metals and alloys have different properties, and some tools may be better suited to certain materials than others. For example, some cutting tools are designed specifically for use with softer metals, while others are better suited to harder materials.

- Precision and accuracy: Precision and accuracy are important factors in metalworking, and the right tool can make all the difference. When choosing a tool, consider the level of precision you require, and look for tools that are designed for accuracy and precision, such as micrometers or calipers.

- Comfort and ease of use: Comfort and ease of use are important considerations when choosing a metalworking tool. Look for tools that are ergonomically designed and have features that make them comfortable to use, such as rubber grips or adjustable handles.

- Durability and reliability: Durability and reliability are key factors to consider when choosing a metalworking tool. Look for tools that are made from high-quality materials and have a proven track record of reliability. Additionally, consider tools that are designed for heavy use and that can withstand the demands of a metalworking shop.

- Price: Price is also an important consideration, especially if you are working within a budget. While it is tempting to go for the cheapest option, it is important to remember that you get what you pay for. High-quality metalworking tools can be expensive, but they will often last longer and provide better results, saving you money in the long run.

Choosing the right metalworking tool requires careful consideration of several key factors, including the task at hand, the type of material you will be working with, precision and accuracy, comfort and ease of use, durability, reliability, and price. By taking the time to choose the right tool for your needs, you can ensure that your metalworking projects are completed with the quality and efficiency you require.

Maintenance and Care of Metalworking Tools

Proper maintenance and care of metalworking tools are essential for ensuring their longevity and performance. Neglecting to care for your tools can lead to decreased performance, reduced accuracy, and even premature failure, so it is important to follow a few key steps to keep your tools in top condition. Here are some tips for maintaining and caring for your metalworking tools:

- Cleaning: Regular cleaning is an important part of maintaining metalworking tools. Dirt, oil, and grime can accumulate on the surface of tools, affecting their performance and accuracy. To clean your tools, use a soft cloth and a mild soap and water solution. Avoid using abrasive cleaners or harsh chemicals, as these can damage the surface of the tool.

- Lubrication: Lubricating metalworking tools is essential for reducing friction and wear and tear, and for ensuring their smooth operation. Use a high-quality lubricant and apply it according to the manufacturer’s instructions.

- Storage: Proper storage of metalworking tools is important for protecting them from damage and ensuring that they are always ready to use when needed. Store your tools in a cool, dry place, and make sure they are protected from moisture and rust. Consider using a toolbox or storage cabinet to keep your tools organized and protected.

- Inspection: Regular inspection of metalworking tools is important for identifying any damage or wear and tear before it becomes a serious issue. Look for signs of wear and tear, such as cracks, chips, or rust, and take action to repair or replace tools as needed.

- Maintenance: Regular maintenance is essential for ensuring the longevity and performance of your metalworking tools. Follow the manufacturer’s instructions for maintenance and keep your tools in good working order by replacing worn parts and tightening loose screws or bolts as needed.

Proper maintenance and care of metalworking tools are essential for ensuring their longevity and performance. Regular cleaning, lubrication, storage, inspection, and maintenance can help to keep your tools in top condition and ready to use when needed.

By taking good care of your metalworking tools, you can ensure that your projects are completed with the quality and efficiency you require.

Safety Tips For Metalworking Tools

Safety should always be a top priority when working with metalworking tools. Whether you are a professional metalworker or a hobbyist, it is important to follow a few simple safety tips to help minimize the risk of injury and ensure a safe working environment. Here are some important safety tips to keep in mind when working with metalworking tools:

- Wear protective gear: Always wear appropriate protective gear when working with metalworking tools, including gloves, safety glasses, and a face shield. This will help to protect you from flying debris, sparks, and other hazards.

- Use the right tool for the job: Make sure you are using the right tool for the job. Using the wrong tool or a tool that is not designed for the task at hand can increase the risk of injury.

- Maintain your tools: Regular maintenance and care of your metalworking tools is essential for ensuring their performance and longevity. It is also important for ensuring the safety of your tools. Regularly inspect your tools for wear and tear, tighten loose screws or bolts, and replace worn parts as needed.

- Secure your workpiece: Secure your workpiece before you begin cutting, drilling, or shaping. Use clamps, vices, or other holding devices to keep the workpiece in place and reduce the risk of movement or slippage.

- Keep your workspace clean and organized: A clean and organized workspace is not only more efficient, but it can also help to minimize the risk of injury. Regularly sweep and clean your workspace, and keep tools and other materials organized and stored in their proper place.

- Unplug tools when not in use: Always unplug metalworking tools when they are not in use. This will help to reduce the risk of electrical shock or fire and ensure the safety of your tools and workspace.

- Know your limits: Know your limits when it comes to working with metalworking tools. If you are unsure about how to use a tool or are not comfortable with a particular task, seek the assistance of a professional or consider taking a metalworking class.

Safety should always be a top priority when working with metalworking tools. By following a few simple safety tips, you can help to minimize the risk of injury and ensure a safe working environment.

Whether you are a professional metalworker or a hobbyist, always make sure to prioritize safety in your metalworking projects.

In a Nutshell

In conclusion, metalworking tools are an essential component of any metalworking project. Whether you are a professional metalworker or a hobbyist, having the right tools for the job is crucial for ensuring the quality and efficiency of your work. From hand tools to power tools, there is a wide range of metalworking tools available, each designed to meet different needs and requirements.

When choosing metalworking tools, it is important to consider factors such as the task at hand, the type of material you will be working with, precision and accuracy, comfort and ease of use, durability, reliability, and price.

Proper maintenance and care of your tools are also essential for ensuring their longevity and performance, so make sure to follow a few simple steps to keep your tools in top condition. Whether you are a seasoned pro or just starting out, metalworking tools can help you to achieve the quality and efficiency you require in your projects.

FAQs

What Are Metalworking Tools?

Metalworking tools are a range of tools and machinery designed for shaping, cutting, and manipulating metal materials. These tools are used in a variety of applications, including welding, machining, forging, and fabrication.

What Are the Different Types of Metalworking Tools?

The different types of metalworking tools include hand tools, power tools, machine tools, and measuring and cutting tools. Examples of hand tools include hammers, chisels, pliers, and files. Power tools include angle grinders, drills, and saws. Machine tools include lathes, mills, and presses. Measuring and cutting tools include calipers, rulers, and saws.

Are the Safety Tips for Operating Metalworking Tools Applicable to Hand and Power Tools as Well?

Yes, the essential safety tips for tool handling are applicable to hand and power tools as well. It is important to always wear protective gear, inspect tools before use, follow proper operating procedures, and keep work areas clean and well-lit to ensure safety when using metalworking tools or any other type of tools.

What Are Some Common Hazards Associated With Metalworking Tools?

Some common hazards associated with metalworking tools include electrical shock, fire, flying debris, cuts, and abrasions. To minimize the risk of injury, it is important to follow safety guidelines and properly maintain and care for your metalworking tools.

How important is it to use the correct metal cutter for safety when operating metalworking tools?

When operating metalworking tools, using the correct metal cutting tools is crucial for ensuring safety. Using the right cutter can prevent accidents and ensure precision when working with metal. It is important to always select the appropriate tool for the specific metalworking task at hand.

What is the Importance of Proper Maintenance and Care of Metalworking Tools?

Proper maintenance and care of your metalworking tools is essential for ensuring their performance and longevity. Regular maintenance and inspection of your tools can help to identify potential issues and prevent them from becoming bigger problems in the future.

What Are Some Common Safety Tips When Working With Metalworking Tools?

Some common safety tips when working with metalworking tools include wearing protective gear, using the right tool for the job, securing your workpiece, keeping your workspace clean and organized, unplugging tools when not in use, and knowing your limits.

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.