Blades with a diameter of 10 inches or 12 inches are used in table saws and compound miter saws. The blades are commonly carbide-tipped, just as those for portable saws. Metal-cutting chop saws (also known as abrasive saws or cut off saws) use 14-inch silicon carbide or aluminum oxide abrasive blades in circular saw blades.

With some limits, a circular saw can be used as a table saw. A circular saw is similar to a table saw in that both features rotating blades. A circular saw is hand-held equipment that cuts through wood, whereas a table saw is a fixed tool that allows the wood to pass over it. Both of them sawed the wood.

A circular saw can be fixed to do some of the same duties as a table saw, but it will never be able to accomplish everything a table saw can do with the same accuracy and convenience. The only benefit you may experience is mobility.

How Do You Convert a Circular Saw to a Table Saw?

The lack of safety measures is the most dangerous aspect of creating a table saw out of a circular saw. A riving knife or kickback pawls can’t be mounted on a homemade table saw since there’s no room. It’s also tough to rig up any kind of blade guard, and it may lead to binding, which would make things worse rather than better.

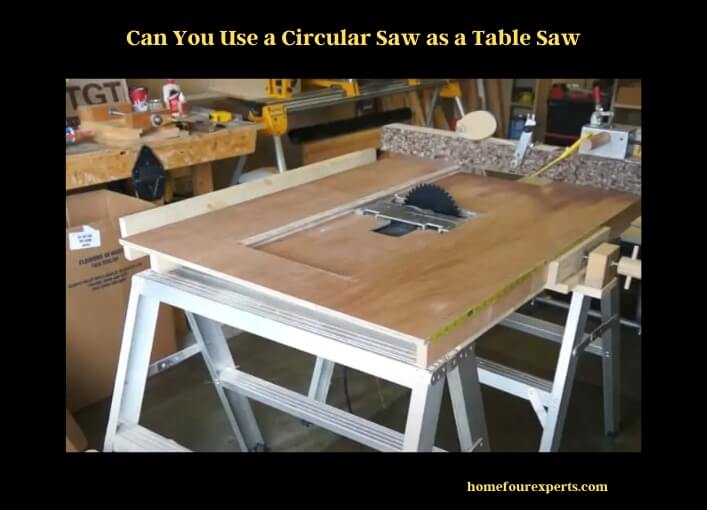

With a specifically constructed table or one you create yourself, you may convert a circular saw into a table saw by slotting the top to enable the saw blade and guard to protrude through. While a circular saw cannot produce the same precise cuts as a table saw, it may be used to tear boards, make rough cuts, and do other light-duty tasks.

1st Step

Build your own power tool accessory table or buy one from one of the companies listed in the Resources section. A rectangular hole 8 inches long and 3/4 inch wide should be cut in the table to fit the circular saw blade and guard. Make sure the table you’re using is solid and large enough to accommodate the stock you’re cutting.

2nd Step

Place the circular saw on the table’s bottom, with the blade passing through the slot and the blade and guard protruding through the table’s upper side. Use the brackets that come with a ready-made table to secure the saw, or use wood screws to fasten it to a homemade table. Make sure the screws don’t go through the table’s top surface.

3rd Step

Calculate the width of the completed board you’ll be cutting. For instance, if you want a 6-inch wide board, measure 6 inches from the blade on the left side of the table as you face the saw from the table’s foot. Make two markings at the 6-inch measurement point: one on the blade’s front and the other on the blade’s back. These parallel markings will help you properly align your guideboard.

4th Step

Connect the saw to the extension cable and place the foot-controlled switch so you can turn it on and off while cutting the board.

5th Step

Line up the two markings with the 1-inch-by-2-inch guide board and clamp it at either end of the table. Start the saw and slide the board you’re cutting into the blade by sliding it along the guide board. Guide the board through the saw slowly until it reaches the last 12 inches. Finish putting the board through the saw with a push stick.

What’s the Difference Between a Circular Saw and a Table Saw?

The table saw and the circular saw are two prominent types of power saws. Both of these saws may be used to cut large and tiny pieces of material to length and can be utilized in a number of applications.

But, if you’re like most others, you’re probably wondering which saw is superior and when to use which one?

The table saw is a stationary instrument that is larger than the circular saw. The circular saw, on the other hand, is a portable power saw, which means it’s smaller than the table saw.

Circular saws are hand-held instruments, whereas table saws are put on a flat surface. Table saws are more costly than circular saws; Circular saws make fewer cuts, but table saws create more precise cuts. Table saws have dust collectors, but circular saws do not.

Choosing the appropriate saw may be difficult, and many woodworkers are unsure whether to buy a table saw or a circular saw.

If you only want one of these two types of power saws and don’t want to invest in both, keep reading because I’ve covered a comparison assessment in today’s post that will help you determine which one is best for your tasks.

Is There a Difference Between a Table Saw Blade and a Circular Saw Blade?

Miter saws, table saws, radial arm saws, cut-off saws, and basic circular saws all employ circular saw blades. Many circular blades can be utilized in a variety of devices.

The key distinction is each’s mobility. Table saws are large, heavy, and difficult to maneuver. Circular saws are smaller, lighter, and more portable than other saws. If necessary, they may also be utilized as a table saw, although table saws cannot be used as circular versions.

Final Words

To even consider getting a project done, the marketing industry will have you believe that you need this, that, and everything in between. Naturally, you begin to doubt yourself and your tools: ‘Well, I have a good circular saw… Do I really need a table saw for that front deck project?’

A decent circular saw, in the hands of someone who understands how to use it, can accomplish anything a table saw can.

Read more:

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.