The most complicated that a beast-level machine holds is the chainsaw we have ever experienced. Even a very useful device that is most handy to handle bigger wood grains. Consisting of versatile and complex machine parts inside and outside, yet perfection comes with the skill and competency of seasons after seasons usage and acknowledgment.

If you are enough recognized by this pretty simple machine, you will get relaxation on the first mysterious performance. However, many users wanna try, yet lack of knowledge through the study time is the greater barrier.

A recent study by the CDC has explained that over 36000 cut-off cases or related different injuries in each year by a complex mix of machinery. So, we have enlisted the entire chainsaw parts and function that you and other prospective users should know to avoid injuries.

Any missed parts? Give a mention of that in the comment section below.

What Does a Chainsaw Look Like?

Chainsaw or Chain Saw, the beast size machine was made back in the 18th century to make out the pelvic bone at ease or within less time with less effort. Its first look was almost the same as the modern kitchen knife which is powered by a hand-crank with little teeth on the blade edge that may wound an oval shape.

The question may arise as to why chainsaws are almost all now for woodworking like cutting big trees to generate something from the wood grain except for being an assistant during childbirth? Later on, in the 19th century, the childbirth chainsaw prototype was developed for further beast and heavy-duty jobs apart from symphysiotomy operations. Why are chainsaws so loud? In general, it comes in 3 common parts, especially the engine that creates distinctive sound chainsaw chain rise to 90dB.

This is an absolute portable electric-powered, gasoline, and battery-powered saw that rip off with a single set of teeth per inch and is attached to a rotating chain. The chain drives a pre-attached guide bar to deal with heavy-duty activities.

What Is a Chainsaw Bar?

The ultimate metal support to hold the chain as it turns around from the engine starts. The bar and chain were sometimes weighted in a single word to think of belonging to chainsaw blades. However, these are 2 separate components of a chainsaw. The equipment determines the cutting length of any of the wood grain that you are working with.

Like another chainsaw, you can fix the chainsaw chain. But first, learning the technique of how to identify your covering is the simplest tactic, not only to determine the chain pitch but also chain gauge by keeping reading the centerline of 3 rivets successively. After that, divide the measurement by 2 and you have the perfect result of the pitch identification number.

Chainsaw Parts and Functions

How many counterparts does a chainsaw bar have? Any guesses? Well, we inform you of at least 5, such as guides, cutters, tie straps, drive links, and rivets. Besides these counterparts, different chain types. Almost all of the chains vary in their link sequences, cutter shapes, and special additions.

The Occupational Safety and Health Administration, in short OSHA, admits that chainsaws have certain parts including the basic ones to encounter a set of safety standards. By identifying an asterisk machine, below parts are enlisted first, especially the gasoline-powered chainsaws

1. Chain

Is chainsaw a saw? With that question, we want to introduce the first part, as in the chain of a chainsaw. This is the vital part to accommodate the cutting job of the wood grain. However, under the BAR, through a closer look, a chain wrap around the bar will be clear. In general, such bar and chain are supplementary not only in cutting jobs but also to handle the object with chain brakes.

Apart from the availability of chain parts and their particularity in sizes, it is in the sharp teeth and the sharp teeth and you can call it gauge. So, it is better to get ready enough work-matching chainsaws as if all models are not universal.

2. Sprocket

In general, people also call it a clutch, fortunately, sprocket and clutch are 2 different pieces of equipment for a chainsaw. We have grouped these, but why? Well, first of all, is a clutch, a small and thin metal ring that covers around the beneath metal disc, whenever start e handguard to make safety, it activates the clutch.

The procedure that a clutch stops the chain from spinning, in fact, before by squeezing the sprocket. Such a metal component we are pointing to take of your clutch and handguard that both can work on the badly required time. Including that disc, both of all pieces, as in the teeth and the surrounding cylinder also comes in a decent configuration. The truth is, in-built sprocket teeth effectively encounter the saw chain.

3. Handheld Equipment

Hand Guard

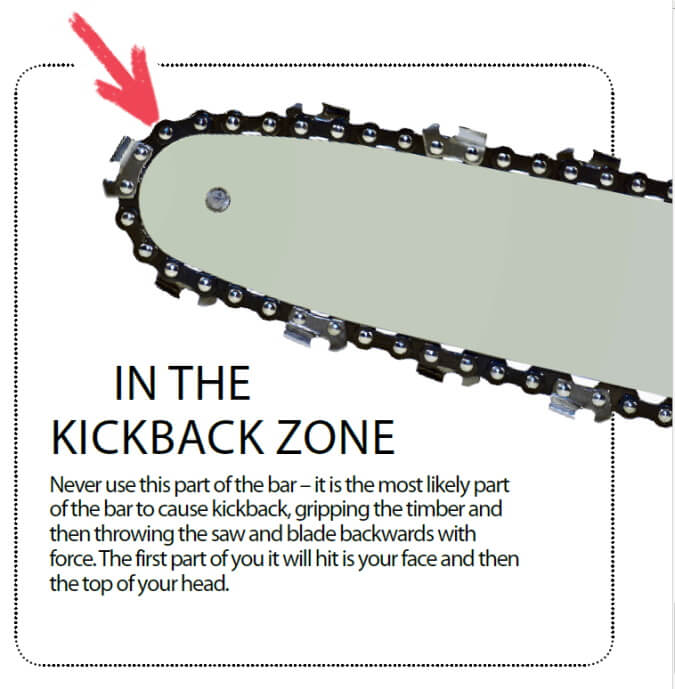

The chain brake or handguard generally shut down the chain’s movement. In terms of avoiding the over usage or spinning of chains while operating with woodworking projects, chain brakes help in sudden shutdown. Kickback is the ultimate name of chainsaw irrelevant movement which can carry hazards to the hooman. However, the incident can occur since the chain type gets nicked for a while, or the chain may get pinched.

Kickback is a quick upward thrust or motion of the chain or blade back towards the prospective user. To avoid all these kickback situations, the chain brake is an assistant for safety and to prevent serious injuries. However, a chain brake is available in both inertia-activated, as in an automated responsive model to respond on the force and manual process as in pressing manually the handguard.

Anti-vibration Handle

As per the counterpart’s name, prevent the machine or its chain from creating vibration. It has typically been designed to remove or reduce strains of operators as if the vibration increases strains on arms, as well as on both hands to lag them behind in accomplishing tasks.

All about is the pre-attached spring and utilizes to absorb the motion of the machine caused by the gas-powered chainsaw’s engine, in fact, the rest of the engine types may also create hyperdensity volumized sounds and vibrations to disturb your headache jobs. While you are using it for longer, for instance, cutting big trees one after another for Xmas home decoration.

Such an anti-vibration system also helps to avoid sounds to help you not distract yourself from work that is busy and determined to do.

4. Muffler

Speaking of which, one of the important parts which also helps in solving the problems in cars. We can make a comparative analysis with it for reducing sounds, sometimes the high-end ones can make the machine sound-proof. Yes, pointing to a muffler on a Husqvarna or Stihl chainsaw.

Besides invaliding noise, the muffler keeps the operator’s ears soundproof while working for long hours and safely lets them work. However, rather than electric-powered or battery-powered chainsaws, gasoline ones create loud noises to damage ears.

5. Chain Catcher

One of the critical features in our list next, and it does exactly as per its name. If the chain acts in a flimsy way or breaks somehow, the possibility increases to hit you as if the thing was wrapped around the bottom of the saw. In general, to prevent such accidents, an integrated small metal hook will deal with either the chain flimsiness or its intended to stop on emergency.

Sometimes it may be available in plastic hook shapes also, yet we found it artery. However, the plastic ones are not that strong to withstand the chain flimsiness, in fact, in terms of handling the situation while the chain comes out of the guide bar all along, it may create other injuries.

Therefore, it is worthy to check out the on-placed safe chain catcher with the chainsaw.

6. Spark Arrestor

This is a mesh-like screen in our enlisted chainsaw parts and functions listing next. Typically it fixes the inside of the muffler on either side or visible site. It functions automatically like a chain catcher while the chain goes through the small projectiles, something like small metal pieces. Until it tries to fly out from the chainsaw, the spark arrestor does not work or you can say it stays calm.

Unlike other featured functions or parts activities of a chainsaw, this function stays calm, yet helpful while in the time of activation to prevent dependency on the situation to damage or any unnecessary injuries.

7. Bucking Spikes

Looks like Bacterium Spikes! This feature is a great assistant to let the chain drive-through trees into logs to get any shape. While driving the spikes into a bigger piece of wood grain, provides a wide range of leverages to the prospective chainsaw man by stabilizing the entire set to get easier cuts through the bigger logs.

Apart from driving capacity, it sometimes gives stressless cuts by your hands by reducing sounds, as well as vibrations to what you will get in gasoline featured chainsaws. Also, your body keeps strains free.

8. Tank

Here you can say the carburetor’s sole purpose is that we have enlisted it here too. However, the carburetor not only keeps fuel motion free thoroughly the engine but also controls the fuel intake.

The tanks are separated into 2 categories according to their 2 sole purposes and other tank functions to keep the engine in perfect motion. Also, tank maintenance is an absolute demand by itself to keep a distance from being involved in accidents.

Fuel

Before the shape and recognition of the fuel tank, you should get acknowledged about the mixing of fuels. The fuel tank is the space where you need to fill up the oil or fuel ratios of the mixture. Almost all of the chainsaw models have a common allowance of mixtures, such as 50:1 or 40:1 of gas/oil and water.

Lubricant

The housing where you can put the chain oil and bar into your chainsaw is popular as a lubricant tank. However, as lubricants to utilize, you can check out the perfect bar and chain oil available in the supermarket. Not only reduces the friction and sounds but also diminishes heating parts by the in-built metal-on-metal contact between a chainsaw’s chain and bar while operating.

There are several techniques to utilize lubricant as per the demand and jobs. If you don’t follow them, it can happen in the opposite friction.

9. Pull Cord

A simple cord is attached with the rubber or plastic handle. You better use to turn on the engine by it for an initial start. Such a pull cord is a blessing with an available break-strength plastic handle while the engine will not start with an on/off switch, you can pull the cord at ease for an initial chainsaw cutting function activation.

But never forget the structure, like the cord is too small as if the very fast or strong pull may tear it off and can occur a big injury instead of cutting off trees.

10. Spark Plug

If you have a car, a small plug or spark plug is noticeable. Similar to that inserted plug, chainsaws have a smaller version of that one. The single purpose of this chainsaw part is to ignite the engine’s fuel, in fact, to get rid of the fractional cases which can cause injuries.

Like a chainsaw’s air filter, within an overtime application, the spark plug can tear off. However, not that much easier, it may require a replacement on special occasions after wearing out. Sometimes the wearing out depends on silly factors which happen due to the lack of maintenance knowledge, for instance, not employing hard plugs and restless usage for hours. Therefore, if you want a replacement, check the strength of the spark plug before purchasing.

11. FlyWheel

The main function for which we love is controlling the chainsaw’s speed. The speed at which the saw mainly works separately for cutting big trees, logs, and mid-sized wooden pieces. Apart from speed control, it also regulates the engine to keep itself cool not only in short-term wood projects but also in big ones.

This internal component is a blessing for smoothing out the engine firing. Besides preventing the engine from overheating, though you need such techniques to utilize this core equipment, it can help the engine start in an instant.

12. Air Filter

Want to get the right fuel mixture pouring into the engine? This is another internal piece of equipment that can get dirty at ease. Besides that, the feasibility of getting damaged and clogged is very common while using it for a short time. Because of the thinner adjustment, it may call for occasional replacement.

Each chainsaw has such parts to clear out the machine’s dust and dirt too. As well as keep particles far from getting inside the carburetor and damaging it. So, ensure always after employing one of the saws that you have clean out air filters or not.

13. Adjustment

Lean

Inside the additional port, it may hole marked with LA, called a precision for lean adjustment screw. This adjustment screw controls the fuel mixture for your chainsaw. Moreover, you need to change the input of the fuel which was poured inside the carburetor.

Similar to low/high adjustment screws, the system for tuning the lean is somewhat involved. Therefore, you should do like us, or we can refer to the chainsaw’s user manual with instructions on how to adjust the lean adjustment screw.

High/low

Along with the lean adjusting screw, there are another 2 top screws marked with H and L. Both are particular as High and Low adjustment and their screws. These are very active making control over the idling speed. However, you can tweak the speed or Revolutions Per Minute (RPM) from the minimum to the maximum level.

The main strategy to make these adjustments may be somewhat involved, and if you need any change, call for the simplest and specific manual instruction.

14. Switch

Choke/ On-off

The chain on/off switch or well-known as a choke that you can control by the single lever. If you see the lever, there is a switch like other electricity-controlling plastic switches at our home. However, you should keep it in the ON position, and if the user flips the switch up, it may stay off. An instant pulling the switch on, you can start using the choke.

Summer/Winter Shutter

Next up is not that much known to users, even this winter or summer shutter is the most commonly misused chainsaw piece. The chainsaw integrates it to control the airflow of the machine while working. It stays near the engine to pull out or pull into the machine and outside from it to keep up the overflow.

Why is it popular with this name? During warm climates or in the summertime chainsaw applications, employing this small, yet stronger component will help in airflow control. In contrast, during the winter usage, to keep the engine warm inside the beast device rather than letting it get cold inside. Such a simple small passageway can block inside the machine to control these dual airflows.

15. Throttle

Next is the perfect trigger piece, an insider integrated switch of the chainsaw handle. This is vital to control the gas engine pedal to ensure the fuel run and motion work through the wood grains. Unless pressing the throttle interlock, the throttle trigger will never function, not even a single initial start.

However, the main key to maintaining the chainsaw’s Revolution Per Minute (RPM). Once the throttle gets released, the cutter or chain will stop running.

Throttle Interlock

Another OSHA mandatory equipment which next fixes on top of the handle. By giving a short thumb pressure as our team members did, it will give an instant start-up like the throttle.

To effectively encounter the saw chain, running the chain or main cutter of the chainsaw, throttle, and interlock throttle near to the handle is the utmost requirement. However, your intention to work in peace and sound and without accidents or damage, even sometimes to avoid misuse, you better employ both buttons at once.

16. Engine

The basic equipment to run the entire beast. Leaving without mentioning a machine engine is an incomplete part of the chainsaw parts and functions article history. A metal block, a shape of a black nut with rubber wrapping behind the spark plug. Attaching all the lines, it just let itself cut off everything.

However, a standard gas-powered chainsaw has this function rather than other multi-powered saws. In this case, you may ask a question that a chainsaw is a saw or not. Then yes, if the engine line attached behind the spark plugs to run across it with the help of lubricant. Apart from the lines, models like battery and electricity aligned ones are updating engines functions and design for better performance and lightweight.

Decompression Valve

Available in specific chainsaw models, for instance, gas-powered chainsaws. This is not standard in engine categories, yet helps in task accomplishment.

Decompression valve you can search or will be noticeable right near to the engine. As we have mentioned, not that much of standard, has been only in-built to release the existing extra pressure from the engine pistons. By that pressure release compulsion, effortless saw starting is available now.

Manual Fuel Pump

If you have work experience like us with the weed eater, lawnmower, caterpillar, and more, a small valve size counterpart is noticeable near to the engine area and this is a manual fuel pump. After giving a short pressure, it works automatically by pulling a small amount of oil or fuel into the bulb.

Besides the decompression valve, it helps in easy engine starting too. However, better than the valve, this is an emergency chainsaw part, and its functions as well to give a good head-start. Along with the fuel tank to the piston behind, it is a compact part.

Chainsaw Kickback

Kickback, a typical incident is common for describing the casual upward chainsaw guide bar’s motion. It can happen in the blink of an eye, even can be dangerous anyhow. The term happens due to the lack of chainsaw cutting technique sense. So, if there is an injury, like 30000 chainsaw-related accidents, remember to keep ready all first aid boxes near to hand.

However, the most common hazards have different causes. For example:

There is a kickback zone and if the chain hits hard to the heavy-weighted object once, it can happen within seconds.

In the middle of cutting off a wood grain, it may pinch sometimes the chain. So, gradually the chain gets stuck and can create accidental issues without the user’s concern.

Other factors, we are enlisting below:

- A dull chain

- Not maintained chainsaws

- Flimsy chainsaw tension

- Incorrectly installed chain parts

- Cracked, broken, and bent chain parts

- Excessive chain depth gauge setting

- Rivets that are loose

- Incorrect chain depth gauge shape

To keep far from happening all these unnecessary incidents, always maintain and inspect thoroughly before every application. However, if the guide bar’s nose is longer, the potential terms of kickback increase.

How Can Understanding Chainsaw Parts and Functions Help Prevent Chainsaw Kickback?

Understanding the causes of chainsaw kickback is crucial to prevent accidents. Knowing the various chainsaw parts and functions allows you to maintain the tool properly and identify potential issues that could lead to kickback. This knowledge helps users operate the chainsaw safely and minimize the risk of kickback.

Final Words

At the bottom line, this is obvious that the chainsaw parts and functions are versatile shapes and provide functions for task accomplishment. After being complex in sizes and compressions, these all are necessary and capable of operating at an efficient level, yet with proper safety. Remember that if this can give safety along with all extra nerds, you should not employ it without appropriate acknowledgment.

In the above portions of today’s article, we have pinpointed the internal and external parts with their functions of a chainsaw to make you understand how to work with and how to maintain.

We never try to push you to spend valuable bucks to negotiate with your skill and acknowledgment. It is time to read up thoroughly and purchase from the best chainsaws. And yes, if any part is missing, just give a knockdown.

Read more:

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.