A metal cutter is commonly referred to as a metal cutting tool.

Metal cutting tools come in a variety of forms and sizes, each designed for specific tasks. From hand-held devices that allow for intricate designs to be made on metals to larger tools that can slice through thick metal slabs, the range is vast. For those working with thin sheets of metal, there are specialized tools that ensure precision and clean cuts. On the other hand, for those dealing with denser and thicker metals, there are robust tools designed to handle the challenge.

For individuals who are keen on DIY projects and need to cut metal at home, there are methods to achieve this even without specialized tools. Yet, for those who prioritize accuracy and clean finishes, investing in precision metal cutting tools is a wise choice. Among the popular tools for cutting sheet metal, some stand out for their efficiency and ease of use, making them favorites among professionals and hobbyists alike.

If you’re interested in a more in-depth look into the world of metal cutting tools, their types, and their applications, we invite you to continue reading the detailed article below.

Metal Cutter Essentials: Names, Types, and Uses

The Basics of Metal Cutters

Definition and primary function

Metal cutters, as the name suggests, are tools designed to slice through metal. Think of them as the kitchen knives of the metalworking world. Just as you wouldn’t use a butter knife to chop vegetables, different metal cutters are designed for specific tasks.

Historical evolution of metal cutting tools

From ancient civilizations to modern workshops, metal cutting tools have come a long way. Early blacksmiths might have used simple chisels, while today’s industries employ advanced machinery. It’s like comparing a horse-drawn carriage to a sports car – both serve a purpose, but one is clearly more advanced.

Common Names and Terminologies

Hacksaw: The foundational tool

Remember the first time you saw a hacksaw? It’s a tool that’s as basic as bread and butter in the metalworking world. With its toothed blade and simple design, the hacksaw has been a go-to for many, from DIY enthusiasts to professional craftsmen.

Modern names and their origins

Names like plasma cutter, angle grinder, and bandsaw might sound futuristic, but they’re just modern tools with fancy titles. It’s like calling a smartphone a “handheld computational device.” Fancy, right?

Types of Metal Cutters: A Categorization

Hand-held metal cutting tools

Ever tried to cut something with the wrong tool? It’s like trying to eat soup with a fork. Hand-held metal cutting tools are designed for portability and those quick jobs where you don’t need a massive machine.

Small metal cutting tools

For those intricate designs and detailed work, small metal cutting tools are your best friends. Imagine trying to create a delicate jewelry piece; you wouldn’t use a sledgehammer, would you?

Thick metal cutting tools

When dealing with robust and thick metals, you need a tool that packs a punch. It’s like needing a bulldozer instead of a shovel to move a mountain of dirt.

Sheet metal cutting tools

Ever tried wrapping a gift with too little wrapping paper? Sheet metals are thin, and they require specialized tools to ensure clean and precise cuts.

Data Insights: Metal Cutter Usage

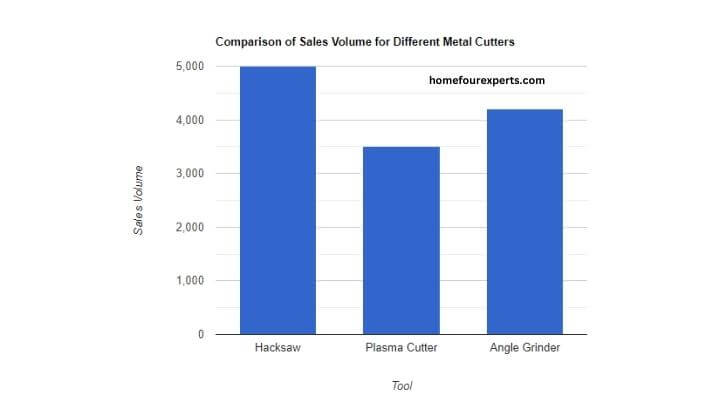

Most Popular Metal Cutting Tools by Sales Volume

| Tool Name | Sales Volume |

|---|---|

| Hacksaw | 5,000 units |

| Plasma Cutter | 3,500 units |

| Angle Grinder | 4,200 units |

Average Lifespan of Common Metal Cutters

| Tool Name | Average Lifespan |

|---|---|

| Hacksaw | 5 years |

| Plasma Cutter | 8 years |

| Angle Grinder | 7 years |

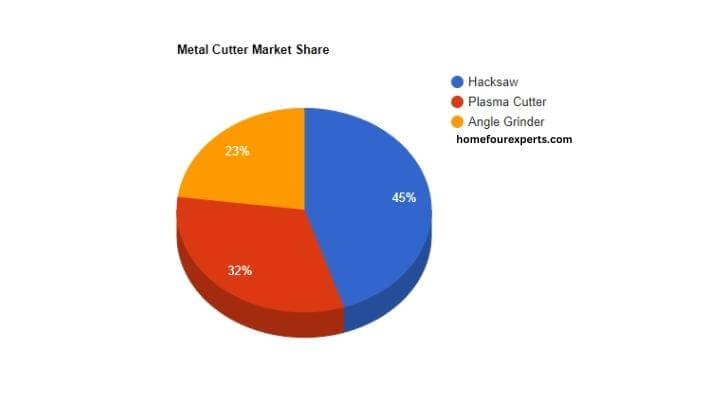

Visual Representation of Metal Cutter Popularity

Comparison of Sales Volume for Different Metal Cutters

Market Share of Various Metal Cutting Tools

DIY Metal Cutting: Techniques and Precautions

Cutting metal without specialized tools

Sometimes, you just have to make do with what you have. It’s like trying to open a can without a can opener. With patience and some ingenuity, you can cut metal even without the fancy tools.

Safety measures and best practices

Just as you wouldn’t run with scissors, working with metal requires caution. Always wear protective gear and ensure your workspace is safe. Remember, it’s always better to be safe than sorry!

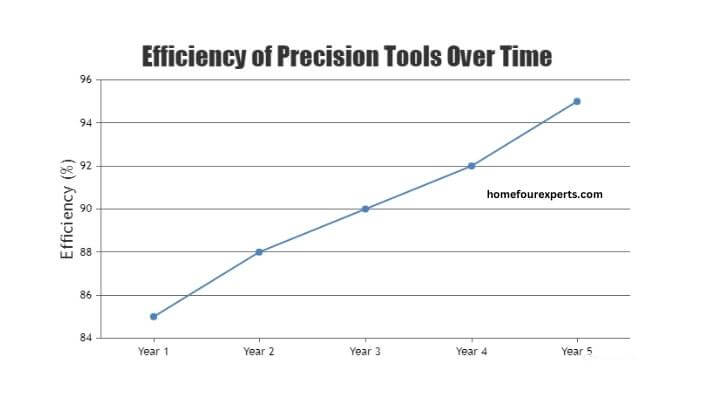

Precision in Metal Cutting

Importance of accuracy and clean cuts

Precision is the name of the game in metal cutting. It’s like trying to fit a square peg in a round hole; if it’s not precise, it won’t work. Clean and accurate cuts ensure the end product is top-notch.

Efficiency of Precision Tools Over Time

Calculator: Estimating Metal Cutting Costs

Factors influencing cost

The cost of metal cutting isn’t just about the tool. It’s like buying a car; you’re not just paying for the vehicle but also for its maintenance, fuel, and other factors. Similarly, factors like material type, tool wear, and labor play a role in metal cutting costs.

Interactive tool for budgeting your metal cutting project

FAQs

What Is the Basic Name for a Metal Cutter?

A metal cutter is commonly referred to as a hacksaw. This tool, with its toothed blade, is designed to cut through various metals. It’s a fundamental tool in metalworking and is often one of the first tools people purchase for DIY metal projects due to its versatility and affordability.

Are There Different Types of Metal Cutters?

Yes, there are various types of metal cutters tailored for specific tasks. For instance, while a hacksaw is great for manual cutting, there are also plasma cutters for more advanced work, angle grinders for grinding and cutting, and bandsaws for continuous cutting. Each tool has its unique application and advantages.

Can All Metal Cutters Handle Any Metal?

Not necessarily. Just like you’d choose a specific knife for a particular kitchen task, metal cutters are designed for specific metals and thicknesses. For instance, while a hacksaw might be great for thin sheets, thick metal beams might require more robust tools like plasma cutters.

What’s the Best Metal Cutter for Home Use?

For home use, a hacksaw is often recommended. It’s versatile, easy to use, and suitable for most DIY projects. Its simplicity and efficiency make it a favorite among homeowners for small to medium tasks.

How Do Professionals Cut Thick Metal?

Professionals often use tools like plasma cutters or oxy-acetylene torches for cutting thick metals. These tools provide the power and precision required for industrial applications and can cut through thick metal sheets or beams with ease.

Is It Possible to Cut Metal Without a Specialized Tool?

Yes, with some ingenuity and patience, it’s possible to cut metal without specialized tools. For instance, using a chisel and hammer can achieve results, but it’s more labor-intensive and might not provide the cleanest cuts. For precision and efficiency, specialized tools are recommended.

How Do I Maintain My Metal Cutter?

Maintenance varies depending on the type of metal cutter. For manual tools like hacksaws, regularly checking the blade for wear and replacing it when needed is essential. For more advanced tools like plasma cutters, following the manufacturer’s guidelines for maintenance, such as cleaning and periodic servicing, ensures longevity and optimal performance.

Metal cutting is an art and a science. From the basic hacksaw to advanced machinery, the tools have evolved, but the goal remains the same: to shape metal to our will. Whether you’re a DIY enthusiast or a professional, understanding your tools and their capabilities can make all the difference. So, the next time you pick up a metal cutter, you’ll know you’re holding a piece of history and innovation in your hands.

About This Writer

Hello, I am David Rowan. I am a professional contractor with 10 years of experience in home building, different tools used, construction, home remodeling, and other home improvement work. I have already built many custom homes and continued to do several woodworking projects along with how to deal with all categories of tools.